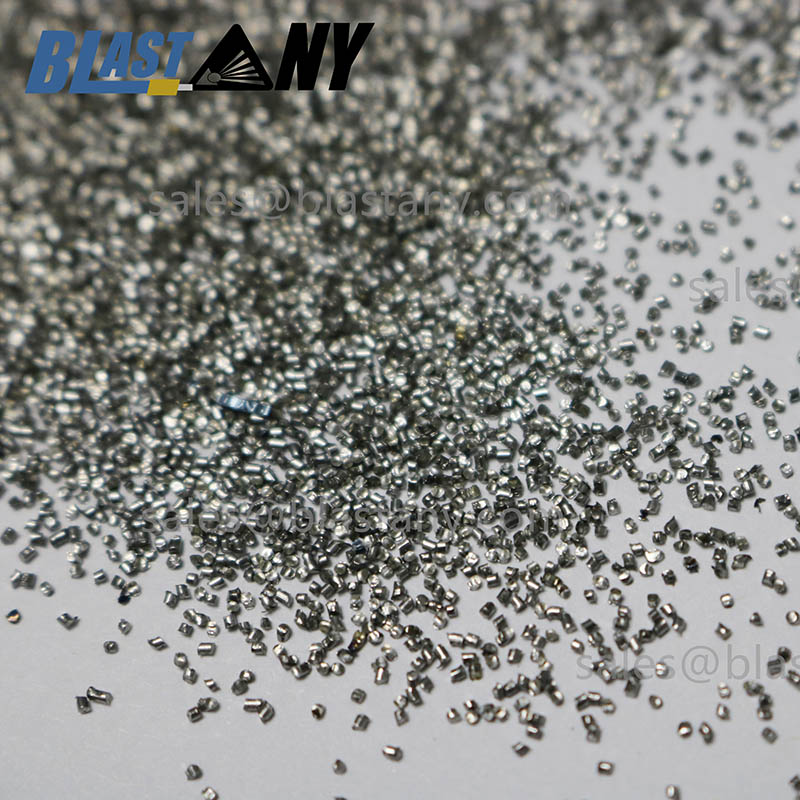

Ho thunngoa ka tšepe e sa hloekang ka theknoloji ea ho etsa atomization

Sebaka sa Kopo

1.Ho qeta bokaholimo ba aluminium zinc die casting le ho hloekisa bokaholimo ba lehlabathe la aluminium. ho fafatsa le ho bentjha bokahodimo ba mmabole wa maiketsetso. Ho hloekisa le ho phethoa ha tšepe e phahameng ea alloy casting surface oxide scale, aluminium alloy enjene block le likarolo tse ling tse kholo tsa ho lahla, kalafo ea 'mabole le kalafo ea antiskid.

2.Aluminium zinki die casting, ho hloekisoa ha holim'a ho lahla ka mokhoa o nepahetseng, ho hloekisoa ka holim'a metsi pele ho ho roala ho khethehileng, ho belisoa ho hloekisitsoeng ha sefahleho sa aluminium ho tlosa melapo ea holim'a metsi, ho hloekisoa ha metsi ka holim'a phala ea koporo ea aluminium, le ho bentša ho hloekisitsoeng ha sejana sa tšepe le valve.

3. Hloekisa lisebelisoa tse batang tsa ho lahlela, chromium plating e shoa bakeng sa ho forging dies and mabili, nchafatsa sekoaelo sa pompo ea supercharger ea koloi, matlafatsa lisebelisoa tse nepahetseng le sesupo sa ho qala, 'me u fafatse ho bentša bokaholimo ba sejana sa tšepe.

4.Aluminium zinc die casting, lebokose la enjene ea sethuthuthu, hlooho ea silinda, carburetor, khetla ea pompo ea mafura a enjene, phala e kenang, senotlolo sa koloi. Bokaholimo ba profil ea lebili le tlase le tla hloekisoa le ho phethoa pele ho penta. Ho phethela le ho hloekisoa ha likarolo tsa tšepe tse se nang tšepe tsa koporo tsa aluminium, likarolo tsa tšepe tse sa hloekang, jj.

Tekheniki Parameters

| Morero | 304 Boleng | 430 Boleng | |

| Motsoako oa lik'hemik'hale% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 | |

| Ni | 5-8% | 0 | |

| Ho thatafala | HRC40-50 | HRC35-50 | |

| Botenya | 7.00 g/cm3 | ||

| Microstructure | austenitic | Ferrite | |

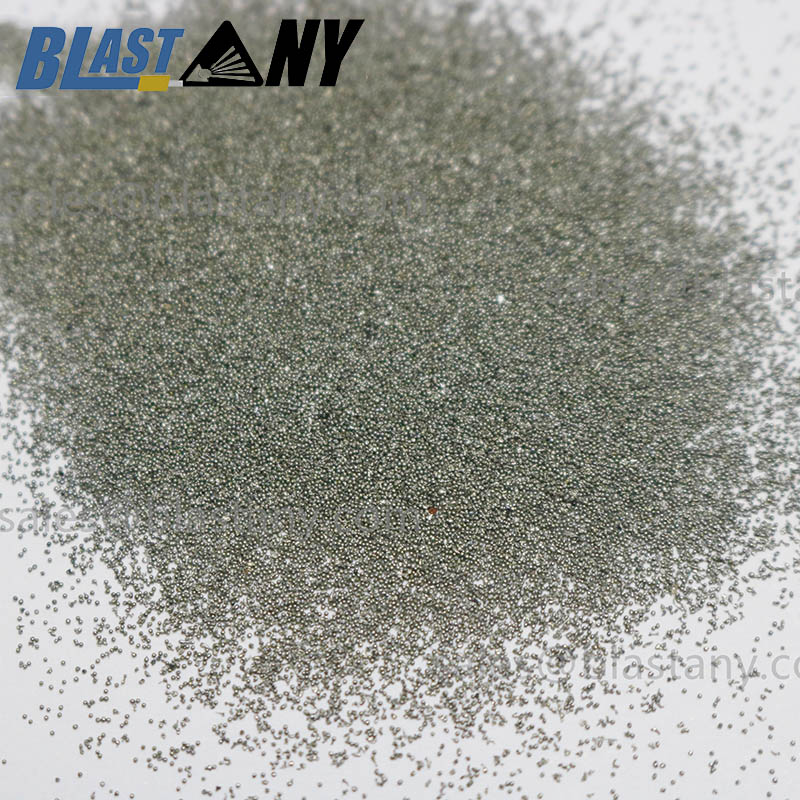

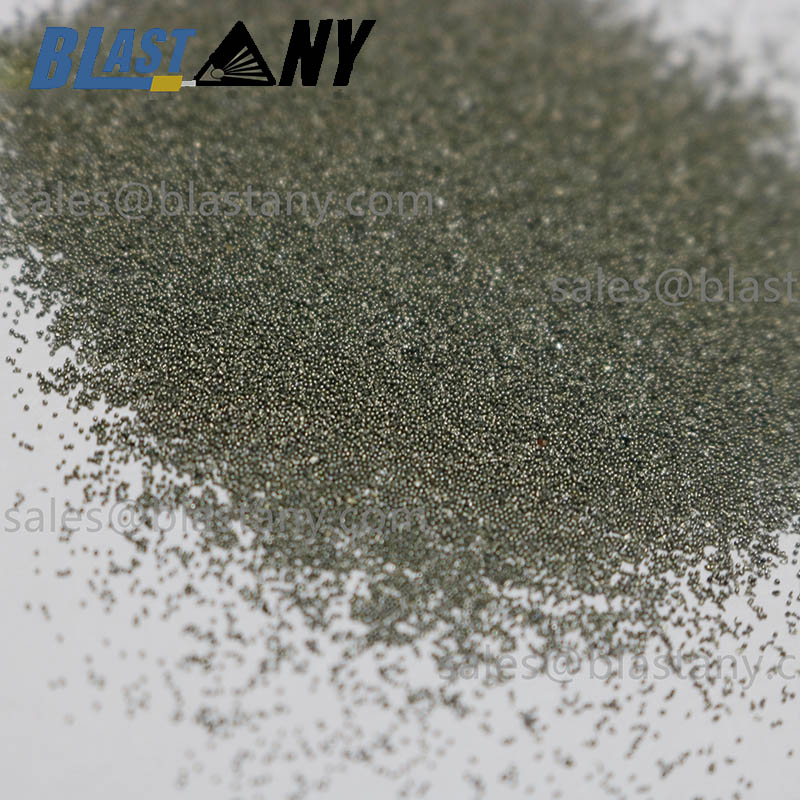

| Ponahalo | Spherical Likaroloana tse sekoti=0% Likaroloana tse sekoti=0% | ||

| Mofuta | 14-18# / 16-20# / 20-25# / 25-30# / 30-40# / 40-70# / 70-140# / 140-270# | ||

| Ho paka | Tone e 'ngoe le e' ngoe ka Pallet e arohaneng 'me tone e' ngoe le e 'ngoe e arotsoe ka lipakete tsa 25KG. | ||

| Ho tšoarella | 27000 ~ 28000 linako tse ling | ||

| Botenya | 7.0g/cm3 | ||

| Kopo | E sebelisoa haholo-holo bakeng sa ho senya le ho qeta holim'a metsi a aluminium die casting, zinki alloy die casting le magnesium alloy die casting; ho qeta bokaholimo ba ho lahla ka mokhoa o nepahetseng, ho lahla tšepe e sa hloekang le boloko ba naha; ho etsa likhalase, ho hloekisa bokaholimo le ho lokisa mefuta e fapaneng ea hlobo. | ||

Kopo

| MOFUTA | Sebaka se khothalelitsoeng sa ts'ebeliso |

| 14-18# | Hloekisa lisebelisoa tse batang tsa ho lahlela, chromium plating e shoa bakeng sa lithaere tsa forging, nchafatsa sekoaelo sa pompo sa supercharger ea koloi, matlafatsa lisebelisoa tse nepahetseng le selemo sa ho qala, 'me u fafatse ho bentša bokaholimo ba sejana sa tšepe. |

| 16-20# | Aluminium zinki die casting, ho hloekisoa ha holim'a ho lahla ka mokhoa o nepahetseng, ho hloekisoa ka holim'a metsi pele ho ho roala ho khethehileng, ho belisoa ho hloekisitsoeng ha sefahleho sa aluminium ho tlosa melapo ea holim'a metsi, ho hloekisoa ha metsi ka holim'a phala ea koporo ea aluminium, le ho bentša ho hloekisitsoeng ha sejana sa tšepe le valve. |

| 20-25# | Aluminium zinc die casting, lebokose la enjene ea sethuthuthu, hlooho ea silinda, carburetor, khetla ea pompo ea mafura a enjene, phala e kenang, senotlolo sa koloi. Bokaholimo ba profil ea lebili le tlase le tla hloekisoa le ho phethoa pele ho penta. Ho phethela le ho hloekisoa ha likarolo tsa tšepe tse se nang tšepe tsa koporo tsa aluminium, likarolo tsa tšepe tse sa hloekang, jj. |

| 25-30# | Aluminium zinc die casting surface finishing, aluminium lehlabathe la ho hlwekisa bokahodimo. Bokaholimo ba 'mabole oa maiketsetso boa fafatsoa le ho bentšoa. |

| 30-40# | Ntle le ts'ebetso ea wg40, bokaholimo ba tšepe e sa hloekang bo boreleli ebile bo botle. Ho theola kalafo ea tšepe ea alloy forgings. Artificial marble surface finishing effect le antiskid treatment. |

| 40-70# | Letlalo le phahameng la alloy steel casting surface oxide, aluminium alloy engine block le likarolo tse ling tse kholo tsa ho lahla lintho tse hloekisang le ho phethela, kalafo ea 'mabole le kalafo ea anti-skid. |

| 70-140# 140-270# | Bokaholimo ba tšepe e entsoeng ka tšepe bo qhibililoe pele bo koaheloa, sebaka sa mabili a koloi, kalafo ea khetla ea enjene, lihlahisoa tsa granite le mehato ea 'mabole ea ho tsitsa le kalafo e khahlanong le skid. |

Granularity

| ScreenNO. | Boholo ba skrine mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0.0555 |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0.0469 |

|

|

|

|

|

|

|

|

| 18 | 1 | 0.0394 |

|

|

|

|

|

|

|

|

| 20 | 0.85 | 0.0331 |

|

|

|

|

|

|

|

|

| 25 | 0.71 | 0.0278 |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0.0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0.0197 |

|

|

|

|

|

|

|

|

| 40 | 0.425 | 0.0165 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0.0117 |

|

|

|

|

|

|

|

|

| 70 | 0.212 | 0.0083 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0.0059 |

|

|

|

|

|

|

|

|

| 140 | 0.106 | 0.0041 |

|

|

|

|

|

|

|

|

| 270 | <0.05 | <0.0019 |

|

|

|

|

|

|

|

|

Lihlopha tsa lihlahisoa