High Hace Hardon

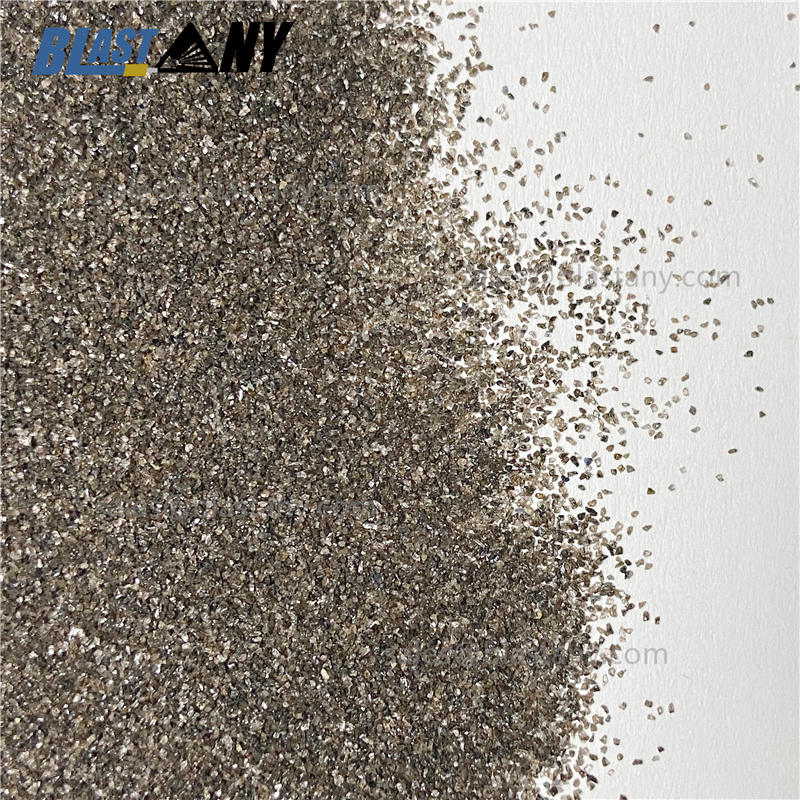

Tlhaloso ea Sehlahisoa

Fokotsa ka har'a lihlahisoa tsa mashala, mashala, tšepe, sekhahla se phahameng sa polasetiki, ho kopanya ha maputsoa, ho lahloa, ho lahla joalo, joalo-joalo, joalo-joalo, E ka sebelisoa hape bakeng sa ho etsa tlhahiso e tsoetseng pele.

Mesebetsi ea eona ea bosoeu:

1.Ka lebaka la matla a ona a phahameng le thepa e 'ngoe, e sebelisoa ho lahlela lehare la tšepe, e fofella libaka tse khethehileng tsa tšepe, lesela le phahameng la bohloeki le phala); Mokhabiso oa 'mele le oa lik'hemik'hale oa' mele oa lik'hemik'hale, spark, mocheso - osele o hanyetsang - koae.

2.Ka lebaka la litšobotsi tsa mathata, thobalano e ntle, matla a maholo, a sebelisitsoeng joalo ka likepe tsa lik'hemik'hale, likaroloana tsa pompo ea lik'hemik'hale; Etsa likarolo tsa mochini, mefuta eohle ea hlobo, e joalo ka terata ea terata ea terata, e squeeze pensele mold molomo, joalo-; Etsa lisebelisoa, liqha tsa matsibolo, lisebelisoa tsa bopaki tsa bullet, manonyeletso a batho, a timelang.

3.Lisebelisoa tsa khokahano tsa Cortundum, tse kang Cortum House Buck Brick le Lihlahisoa tsa Leseli la Moferefere, Pholoho ka bobeli e Tlamo le Tsona. Moholi oa Emery boholo ba Emery o entsoe ka bosholu ba maiketsetso, o sebelisa rolar, ho ts'oaroa ha bolo, Barmark le lisebelisoa tse ling ke F8-F325. Haholo-holo e ne e sebelisoa haholo bakeng sa polishing, ho sesa, ho sesa, ho ts'oaroa hape ho ka hlatsuoa ho latela litlhoko tsa bareki, ho fihlela litlhoko tse ling tsa bareki.

Low Coritum brown Cittundum ka mor'a ho khatholla, e le hore sehlahisoa se sebe se se ke sa phatloha, ho se tsotelle, indasteri ea boithabiso e tala. Haholo-holo e ne e sebelisoa haholo bakeng sa ceramic Abramse alaramic Abrambad, about a mabanta a sootho.

Litekanyetso tsa tekheniki

| PRoduct Lebitso | MMefuta e meng | Lho tsoa Letšoao | Letsoalo | Ponahalo | Hardness (Mohs) | Micro Hardness | Lintlha tsa ho qhibiliha (ºC) | Max Mocheso (ºC) | Ngaka ea Bulk (G / cm3) | Kopo | Boholo | Boholo ba lijo-thollo | |||

| Al2O3 | Fe2O3 | Sio2 | Tio2 | ||||||||||||

| A+ | ≥95 | ≤0.3 | 1-3 | 1.5-3.8 |

3.85g / cm3 | Karolo e khubelu e sootho |

≥9.0 |

Hv2200-2300 |

2250 |

1900 |

1.75-1,95g / cm3 | Lisebelisoa tsa ho pheta-pheta, khang e ntle |

16 # -325 # kapa ho latela moreki |

F12-F1200, 0-1MM, 1-3mm, 3-5mm, 5-8mm, 5-12mm | |

| A | ≥90 | 2-5 | 1-4 | 1-4 | Granular granular grawn powdery | Sepolishe, grind | |||||||||

| B+ | ≥85 | 3-8 | 1.5-4 | 2-4 | Granular granular grawn powdery | Ho silila, lebili le ntseng le cheka, likotoana, sandblas, sandblate | |||||||||

| B | ≥80 | 6-10 | 2-5 | 3-5 | Granular granular grawn powdery | Sepolishe, grind | |||||||||

| C | ≥70 | 8-15 | 9-15 | 4-6 | Granular granular grawn powdery | EPOXY | |||||||||

Mekhahlelo ea lihlahisoa