Lisebelisoa tsa tšepe tsa boleng bo phahameng tse nang le khanyetso e phahameng ea ho roala

Tsebisa

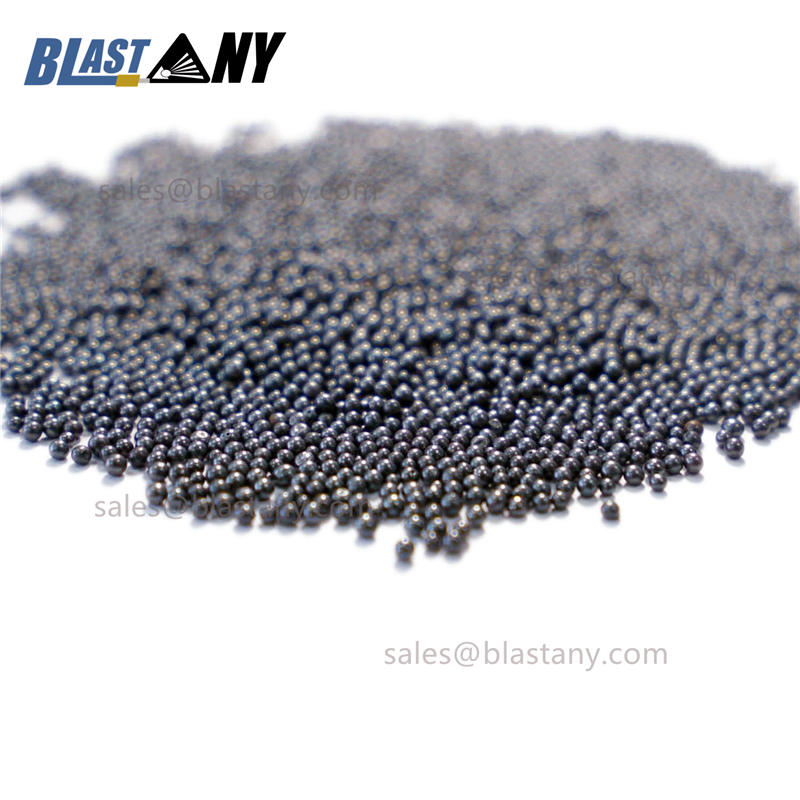

Junda Steel Shot e entsoe ka ho qhibilihisa likhechana tse khethiloeng ka seboping sa motlakase.Sebopeho sa lik'hemik'hale tsa tšepe e qhibilihisitsoeng se hlahlojoa le ho laoloa ka thata ke spectrometer ho fumana litlhaloso tsa SAE Standard.Tšepe e entsoeng ka ho qhibilihisoa e na le atomo mme e fetoloa hore e be karoloana e chitja 'me ka mor'a moo ea tima le ho halefa ka mokhoa oa ho phekola mocheso ho fumana sehlahisoa sa boima bo lekanang le microstructure, se hlahlobiloeng ka boholo ho latela litlhaloso tsa SAE Standard.

Junda indasteri tšepe thunngoa e arotsoe ka tse 'nè, naha maemo a tloaelehileng a lahla tšepe thunngoa, e nang le chromium lahleloa tšepe thunngoa, lipilisi bakeng sa tlaase carbon tšepe, tšepe e sa hloekang, ho akarelletsa le naha maemo a tloaelehileng a lahla tšepe thunngoa ke ka ho feletseng ho ea ka ditlhoko tsa naha maemo a lintho tse content ka tlhahiso, le element ea chromium cast steel shot, e ipapisitse le maemo a naha a libolo tsa tšepe, ho eketsa ts'ebetso ea ho qhibiliha ea ferromanganese ferrochrome likarolo tsa tlhahiso, joalo ka Owen phela nako e telele;Ts'ebetso ea tlhahiso ea tšepe e tlase ea k'habone le lithunya tsa tšepe tse tloaelehileng tsa naha, empa thepa e tala ke tšepe e tlase ea k'habone, litaba tsa khabone li tlase;Ho thunngoa ka tšepe e sa hloekang ho hlahisoa ka mokhoa oa ho etsa atomizing, lisebelisoa tse tala ke tšepe e sa hloekang, 304, 430 tšepe e sa hloekang joalo-joalo.

Mofuta ona oa ho thunya o etselitsoe ho sebelisoa ha ho qhomisoa le ho qhomisa ka tlas'a khatello ea moea o hatelitsoeng.Ha e le hantle e sebelisoa ho lirafshoa tse se nang ferrous tse kang aluminium, li-alloys tsa zinki, litšepe tse sa hloekang, boronse, koporo, koporo ...

Ka mefuta e mengata ea li-grading, e sebelisetsoa ho hloekisa, ho senya, ho kopanya, ho penta le mekhoa ea ho qeta ka kakaretso, likarolong tsa mefuta eohle, ntle le ho silafatsa bokaholimo ba eona ka lerōle la ferrous le senyehang le ho fetola 'mala oa litšepe tse hloekisitsoeng.bakeng sa ts'ebetso ea botsofali ea 'mabole le granite.

Tšebeliso ea indasteri

Ho phatloha ha tšepe

Ho thunngoa ka tšepe ho hloekisa lehlabathe la ho lahla le ho chesoa - lehlabatheng la ho lahla ho etsa hore bokaholimo bo fumane bohloeki bo botle le bohloeki bo hlokahalang, e le hore e ka ba molemo ho ts'ebetso e latelang le ho roala.

Cast steel shot bakeng sa ho lokisa holim'a tšepe ea tšepe

Cast steel shot e hloekisa letlalo la oxide, mafome le litšila tse ling ka ho thunya Blasting, ebe o sebelisa vacuum cleaner kapa moea o hatelitsoeng ho hloekisa bokaholimo ba lihlahisoa tsa tšepe.

Lithunya tsa tšepe tse sebelisetsoang mechini ea Boenjiniere

Lithunya tsa tšepe tse sebelisetsoang ho hloekisa Mechini li ka tlosa mafome, li-welding slag le letlalo la oxide, tsa felisa khatello ea ho cheselletsa, le ho eketsa matla a tlamang lipakeng tsa ho tlosa mafome le tšepe, ka hona tsa ntlafatsa haholo boleng ba ts'ebetso ea mochini oa boenjiniere.

Boholo ba sethunya sa tšepe bakeng sa ho hloekisa poleiti ea Stainless steel

E le hore ho finyelloe phekolo e hloekileng, e khanyang, e khanyang ka holim'a tšepe ea tšepe e sa hloekang, e tlameha ho khetha lisebelisoa tse loketseng tsa abrasive ho tlosa sekala holim'a tšepe e batang.

Ho ea ka limaraka tse fapaneng, bokaholimo ba tšepe bo hloka ho khetha li-abrasives tse fapaneng tsa bophara le karolo ea ho sebetsa.Ha ho bapisoa le mokhoa o tloaelehileng oa lik'hemik'hale, o ka fokotsa litšenyehelo tsa ho hloekisa le ho finyella tlhahiso e tala.

Mecha ea phatlalatso ea lithunya tsa tšepe bakeng sa Pipeline anti-corrosion

Liphaephe tsa tšepe li hloka phekolo ea holim'a metsi e le hore li matlafatse ho hanyetsa ha kutu.Ka ho thunngoa ha tšepe, ho phatloha ha mecha ea litaba, ho hloekisa le ho tlosa oxide, 'me li-attachments li finyella mafome a kōptjoang ho tlosa mafome le botebo ba lijo-thollo, eseng feela ho hloekisa holim'a metsi empa hape ho khotsofatsa ho khomarela pakeng tsa phala ea tšepe le ho roala, ho finyella phello e ntle ea anti-corrosion.

Steel shot peening ho matlafatsa

Likarolo tsa tšepe li sebetsa maemong a cyclic loading mme li tlas'a khatello ea libaesekele li hloka ho thunngoa ho matlafatsa ts'ebetso ho ntlafatsa bophelo ba mokhathala.

Lahlela tšepe thunngoa Application domains

lithunya tsa tšepe li sebelisoa haholo ho matlafatsa ts'ebetso ea likarolo tsa bohlokoa joalo ka selemo sa helical, spring ea makhasi, bar e sothehileng, lisebelisoa, likarolo tsa phetisetso, bethe, cam shaft, axle e kobehileng, molamu o kopanyang joalo-joalo.Ha sefofane se theoha, lisebelisoa tsa ho theola li tlameha ho mamella ts'usumetso e matla eo se hlokang kalafo ea ho thunngoa khafetsa.Mapheo a boetse a hloka phekolo ea nako le nako ea khatello ea maikutlo.

Tekheniki Parameters

| Morero | Melao ea Sechaba | Boleng | |

| Motsoako oa lik'hemik'hale% | C | 0.85-1,20 | 0.85-1.0 |

| Si | 0.40-1.20 | 0.70-1.0 | |

| Mn | 0.60-1.20 | 0.75-1.0 | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Ho thatafala | tšepe ea tšepe | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Botenya | tšepe ea tšepe | ≥7.20 g/cm3 | 7.4g/cm3 |

| Microstructure | Tempered Martensite kapa Troostite | Tempered Martensite Bainite Composite mokhatlo | |

| Ponahalo | Spherical Likaroloana tse se nang letho <10% Crack particle <15% | Spherical Likaroloana tse se nang letho <5% Crack particle <10% | |

| Mofuta | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Ho paka | Tone e 'ngoe le e' ngoe ka Pallet e arohaneng 'me tone e' ngoe le e 'ngoe e arotsoe ka lipakete tsa 25KG. | ||

| Ho tšoarella | 2500 ~ 2800 linako tse ling | ||

| Botenya | 7.4g/cm3 | ||

| Diameter | 0.2mm, 0.3mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.4mm, 1.7mm, 2.0mm, 2.5mm | ||

| Lisebelisoa | 1. Ho hloekisoa ha ho phatloha: E sebelisetsoa ho hloekisa seqhomane sa ho lahla, ho bolaea, ho qhekella;ho tlosoa ha lehlabathe la ho lahla, poleiti ea tšepe, tšepe ea mofuta oa H, mohaho oa tšepe. 2. Ho tlosoa ha mafome: Ho tlosoa ha mafome a ho lahla, ho qhekella, poleiti ea tšepe, tšepe ea mofuta oa H, mohaho oa tšepe. 3. Shot peening: Shot peening ea gear, mocheso tšoaroa likarolo. 4. Ho phatloha ho thunngoa: Ho thunngoa ha tšepe ea profil, boto ea sekepe, boto ea tšepe, thepa ea tšepe, mohaho oa tšepe. 5. Kalafo ea pele: Phekolo ea pele ea holim'a metsi, boto ea tšepe, tšepe ea profil, mohaho oa tšepe, pele ho penta kapa ho roala. | ||

Size Distribution Of Steel Shot

| SAE J444 Standard Steel shot | Screen No. | In | Boholo ba skrine | |||||||||||

| S930 | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| TSOHLE lia feta | 6 | 0.132 | 3.35 | |||||||||||

| Tsohle Phasa | 7 | 0.111 | 2.8 | |||||||||||

| 90% mets | Tsohle Phasa | 8 | 0.0937 | 2.36 | ||||||||||

| 97%mets | 85% mets | Tsohle Phasa | Tsohle Phasa | 10 | 0.0787 | 2 | ||||||||

| 97%mets | 85% mets | 5% boholo | Tsohle Phasa | 12 | 0.0661 | 1.7 | ||||||||

| 97%mets | 85% mets | 5% boholo | Tsohle Phasa | 14 | 0.0555 | 1.4 | ||||||||

| 97%mets | 85% mets | 5% boholo | Tsohle Phasa | 16 | 0.0469 | 1.18 | ||||||||

| 96% mets | 85% mets | 5% boholo | Tsohle Phasa | 18 | 0.0394 | 1 | ||||||||

| 96% mets | 85% mets | 10% boholo | Tsohle Phasa | 20 | 0.0331 | 0.85 | ||||||||

| 96% mets | 85% mets | 10% boholo | 25 | 0.028 | 0.71 | |||||||||

| 96% mets | 85% mets | Tsohle Phasa | 30 | 0.023 | 0.6 | |||||||||

| 97%mets | 10% boholo | 35 | 0.0197 | 0.5 | ||||||||||

| 85% mets | Tsohle Phasa | 40 | 0.0165 | 0.425 | ||||||||||

| 97%mets | 10% boholo | 45 | 0.0138 | 0.355 | ||||||||||

| 85% mets | 50 | 0.0117 | 0.3 | |||||||||||

| 90% mets | 85% mets | 80 | 0.007 | 0.18 | ||||||||||

| 90% mets | 120 | 0.0049 | 0.125 | |||||||||||

| 200 | 0.0029 | 0.075 | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Mehato ea Tlhahiso

Lisebelisoa tse so ntlafatsoe

Ho theha

Ho omisa

Tlhahlobo

Khetho

Ho halefisa

Tlhahlobo

Sephutheloana

Lihlopha tsa lihlahisoa