Lifaha tsa khalase tse nang le li-index tsa refractive tsa 1.9 le 2.2

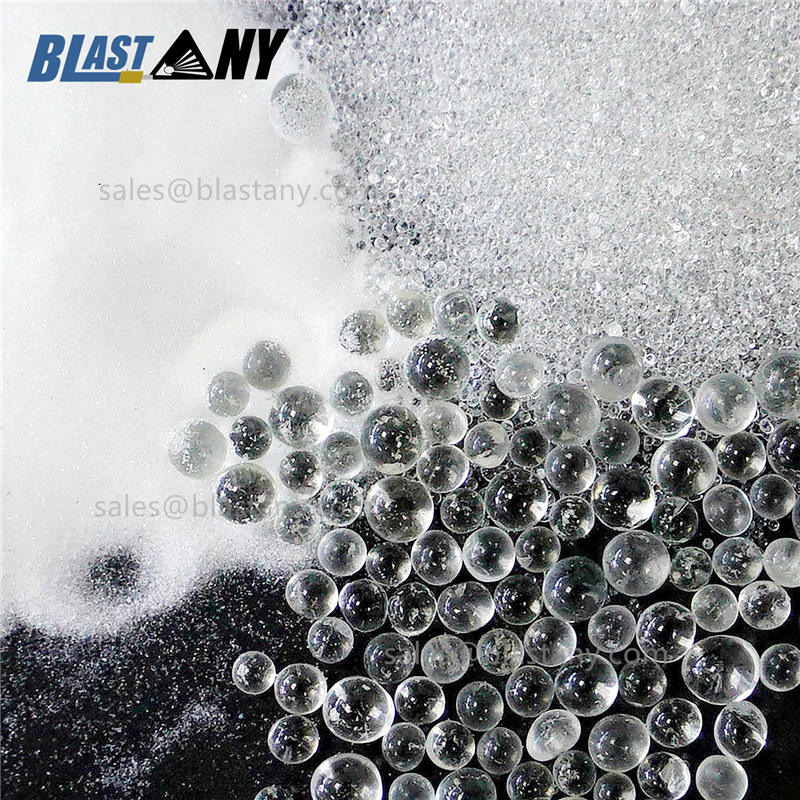

Sandblasting Glass Beads

Junda glass bead ke mofuta oa abrasive blasting bakeng sa ho qeta bokaholimo, ka ho khetheha ho lokisa litšepe ka ho li thethefatsa. Ho phatloha ha lifaha ho fana ka tlhoekiso e holimo ho tlosa pente, mafome le liphahlo tse ling.

Mokhoa oa ho qhomisa lifaha tsa khalase ha o na tikoloho ebile ha o na lik'hemik'hale 'me o ka sebelisoa ho lemoha mefokolo ea weld le solder. Melemo ea ho sebelisa likhalase tsa khalase e kenyelletsa:

●Mefuta e mengata ea limaraka e fumanehang bakeng sa mesebetsi le liprofaele tse fapaneng.

●Ha e kena-kenane le li-coatings kaha ha e sebetse.

●Ha e siee mesaletsa kapa litšila tse kentsoeng, hape ha e bake phetoho efe kapa efe ea bokaholimo.

●E ntlafalitse ho hanyetsa kutu le bokhoni ba ho theola mefokolo ea bokaholimo.

●Ha ho na silika ea kristale e fumanehang.

E sebetsa joang?

Ho phatloha ha lifaha tsa Junda Glass ha e le hantle ho sebelisa lifaha tse ntle tsa khalase tsa boholo bo fapaneng ka likhato tse fapaneng tsa khatello. Maqhubu a manyenyane a khalase a etsa hore sebaka se be bonolo ha likotoana tse kholo li hlahisa sephetho se entsoeng ka mokhoa o eketsehileng.

Lifaha tsa khalase ha li tlose tšepe leha e le efe ea motheo kapa ho kenya bokaholimo. E tla hlahisa qetello e betere, e ts'oanang haholoanyane ha e ntse e eketsa khanya kapa khanya karolong.

E na le lisebelisoa tse fapaneng, ho kenyelletsa:

●Qetello: E ka sebelisoa mefuteng e mengata ea lisebelisoa, ho kenyelletsa le tšepe, khalase, polasetiki le rabara.

●Ho hloekisa: Ntle le ho baka phetoho ea bokaholimo, ho phatloha ha lifaha tsa khalase ho tlosa/hloekisa lintho tse tsoang kantle ho naha.

●Deburring: Bakeng sa ho kopanya le ho sebetsa likarolo, likhutlo le lithapo li ka hloka ho ts'oaroa. Ho phatloha ha lifaha tsa khalase ho ka tlosa li-burrs le mahlakore a masiba ha ho ntse ho netefatsa hore ha ho tšepe e ka holimo e tlosoang.

●Peening: Peening e lelefatsa bophelo ba likarolo tsa tšepe ka ho loantša mapetsong a khatello ea maikutlo le ho bola.

Lifaha tsa khalase bakeng sa ho tšoaea bokaholimo ba litsela

Sefaha sa khalase se tšoaeang sa Junda Road se entsoe ka lehlabathe la khalase, khalase ea litšila e le lisebelisoa tse tala, kamora hore mocheso o phahameng o qhibilihe mme o thehe likhaba tse nyane tsa khalase, ka tlas'a microscope e le sephara se se nang mebala, bophara bo pakeng tsa li-microns tse 75 ho isa ho li-microns tse 1400, hajoale tlhahiso e kholo ea lifaha tsa khalase tse bonahatsang tsela ke mokhoa o phaphametseng oa lelakabe.

Lifaha tsa khalase tse tšoaeang Junda Road li sebelisoa haholo mofuteng o tloaelehileng oa mocheso, mofuta o chesang oa ho qhibiliha o tšoaeang tsela, e le 'ngoe e le lintho tse entsoeng ka premixed, o ka netefatsa ho tšoaea nakong ea bophelo ba ho nahanisisa, e le' ngoe sebakeng sa ho tšoaea bokaholimo ba kaho, e ka bapala phello e hlakileng.

Lifaha tsa khalase li sebelisoa e le mofuta oa ts'ebetso e phahameng, lisebelisoa tsa manyolo ho ea ka ntle ho lifaha tsa khalase, ho etsa hore likhahla tsa khalase li fokolise mokhoa oa ho ba lerōle moeeng, ka lebaka la likhalase tse nang le lisebelisoa tse khethehileng tsa ho kopanya, ho ntlafatsa lifaha le matla a kopantsoeng a ho roala ho ka thibela likhalase tse ling tse nyenyane tsa khalase ho koahela holim'a metsi, hobane li na le lifaha tse nyenyane tsa khalase ha li phaphamala. sebaka se seholo sa holim'a metsi, se ka eketsa sekhahla sa ts'ebeliso ea ho feta 30%, joale lifaha tsa khalase tse benyang li fetohile ntho e ke keng ea fetoloa e bonahatsang lihlahisoa tsa polokeho tseleng.

Re ka fana ka lifaha tsa khalase tse nang le index e fapaneng ea refractive ea 1.53, 1.72, 1.93 joalo-joalo, Re ka fana ka lifaha tsa khalase tsa maemo a fapaneng a naha, kapa ho latela kabo ea boholo e fanoeng ke bareki.

Re fana ka lifaha tsa khalase tse tloaelehileng tse latelang

Maemo a Sechaena: GB / T 24722 - 2009 No.1, 2, 3

Korea Standard: KSL 2521 No.1 le 2

Maemo a Brithani: BS6088 Sehlopha sa A le B

Maemo a Amerika: AASHTO M247 mofuta oa 1 le mofuta oa 2

Tekanyetso ea Europe: EN1423 le EN1424

Tekanyetso ea Turkey: TS EN1423

Maemo a New Zealand: NZS2009: 2002

Tekanyetso ea Taiwan: CNS

Tekanyetso ea Japane: JIS R3301

Maemo a Australia a Maemo a Australia : A, B, C, D

Ho sila Lifaha tsa Khalase

Junda Grinding bead ke mofuta oa sefaha sa khalase se nang le boholo bo lekanang, bokaholimo bo boreleli, boima bo phahameng le botsitso bo botle ba lik'hemik'hale. Lifaha tse silang ka kakaretso ke lifaha tsa khalase tse nang le boholo bo boholo ho feta 1mm. Ha li na 'mala ebile li hlakile ka chebahalo 'me li qitikoe tse hloekileng. E sebelisoa haholo ho dae, pente, enke, indastering ea lik'hemik'hale le lintho tse ling tse qhalakang, ho sila le lisebelisoa tsa ho tlatsa.

Re ka fana ka 0.8 1.2, 1.0, 1.5, 1.5, 2.0, 2.0, 2.5, 2.5, 3.0, 3.0, 3.5 mm boholo ba tsena tse seng kae.

Hape ho latela litlhoko tsa bareki.

Kopo

1.Likarolo tsa lifofane tsa li-bead, ho felisa khatello ea maikutlo, ho matlafatsa matla a mokhathala, le ho fokotsa likhohlano le ho khathala;

2.Phekolo ea anodic le electroplating pele e sebetsa, ntle le ho hloekisa ho ka eketsa ho khomarela;

3. Stainless steel workpiece welding pass hlwekisa le ho tloswa ha mokwapo le dintho tse ding tsa bokgabane;

4. Ho hloekisa le ho senya hlobo ea terata;

5. ho fokotseha ha hlobo ea rabara;

Tekheniki Parameters

| Morero | Boleng | |

| Motsoako oa lik'hemik'hale% | SiO2 | >72% |

| CaO | >8% | |

| Na2O | <14% | |

| MgO | >2.5% | |

| Al2O3 | 0.5-2.0% | |

| Fe2O3 | 0.15% | |

| Ba bang | 2.0% | |

| Refractive Index | N≥1.5% | |

| Botenya | 2.4-2.6g/cm3 | |

| Kabo ea boholo | Ho feta boholo ≤5% ka tlase ho boholo ≤10% | |

| Wire bophara | 0.03-0.4mm | |

| Ho tšoarella | 3-5 % | |

| Ho thatafala | 6-7 MOHS; 46HRC | |

| Microhardness | ≥650kg/cm3 | |

| Sedikadikwe | Sekhahla sa ≥85% | |

| Ponahalo | e se nang mebala, khalase e bonaletsang ntle le litšila, E chitja ebile e boreleli | |

| Kopo | 1.Ho sila 2.Pente e tšoaeang litsela 3.Ho phatloha ha lehlabathe | |

| Litaba tse ka sehloohong | Ha ho na litaba tse etellang pele, fihla maemo a 16CFR 1303 Lead ea Amerika | |

| Likahare tsa lintho tse kotsi | Ka tlase ho maemo a Amerika 16CFR 1500 | |

| Teko ea mollo o tukang | Ho chesa ha bonolo, fihla American 16CFR 1500.44 standard | |

| Metsoako ea tšepe e boima e qhibilihang | Metal content ea soluble matter ratio sekgahla sa boima bo tiileng ha se fete boleng bo tsamaellanang ba ASTM F963 | |

| Sephutheloana | ||

| Mofuta | Mesh | Micronsm Max(μm) | Li-Microns Min(μm) |

| 30# | 20-40 | 850 | 425 |

| 40# | 30-40 | 600 | 425 |

| 60# | 40-60 | 425 | 300 |

| 80# | 60-100 | 300 | 150 |

| 100# | 70-140 | 212 | 106 |

| 120# | 100-140 | 150 | 106 |

| 150# | 100-200 | 150 | 75 |

| 180# | 140-200 | 106 | 75 |

| 220# | 140-270 | 106 | 53 |

| 280# | 200-325 | 75 | 45 |

| 320# | >325 | 45 | 25 |

Lihlopha tsa lihlahisoa