AISI1010/1015/1085 High/Low carbon steel ball 0.8 mm - 50.8 mm Carbon steel ball bakeng sa mabili a dibaesekele tsa ketane

Tlhaloso ea Sehlahisoa

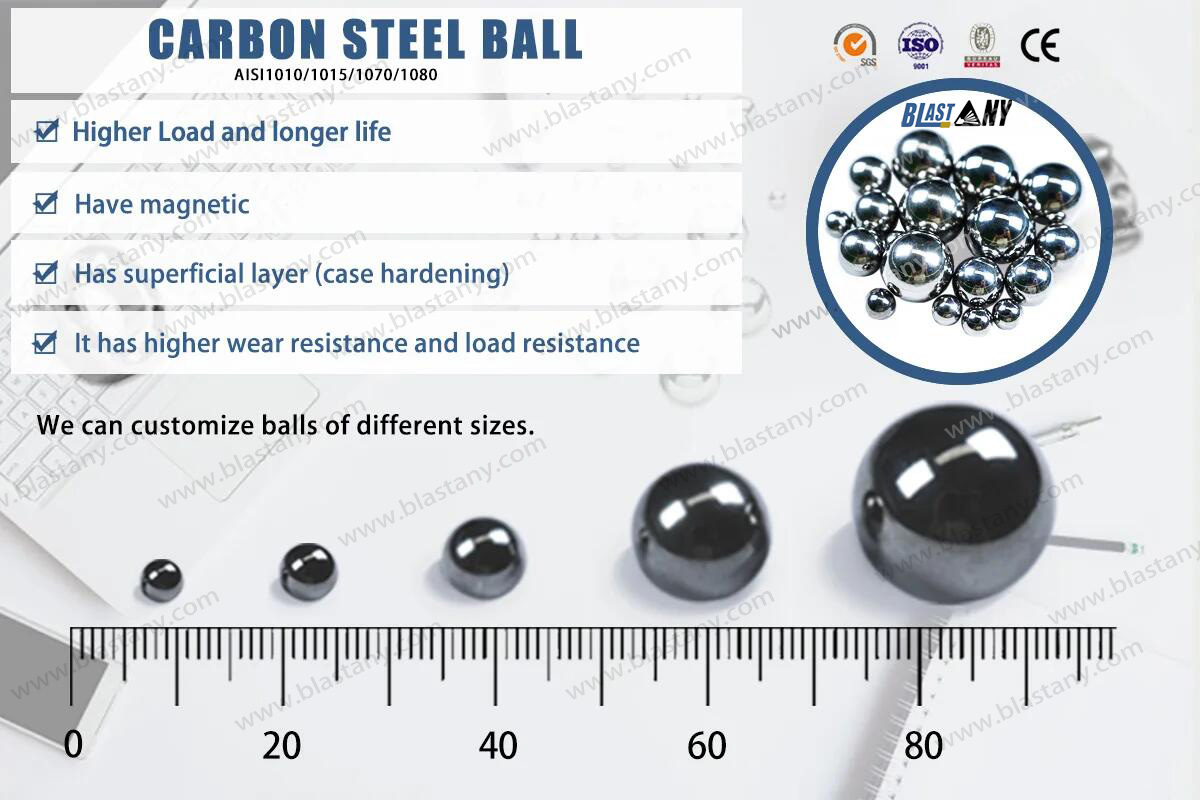

Ball ea tšepe e tlase ea Carbon.

| Lintho tse bonahalang | AISI1010/1015 |

| Boholo Range | 0.8mm-50.8mm |

| Kereiti | G100-G1000 |

| Ho thatafala | HRC: 55-65 |

Tlhaloso ea Sehlahisoa

Likaroloana:

e na le matla a khoheli, Libolo tsa tšepe tsa Carbon li na le lera le ka holimonyana (ho thatafatsa nyeoe), ha karolo e ka hare ea bolo e ntse e le bonolo, sephutheloana hangata se na le oli. Hangata electroplating ha e le ka ntle, e ka kenngoa ka zinki, khauta, nickel, chrome joalo-joalo. ho ba le ts'ebetso e matla ea ho thibela ho apara .Papiso : ho hanyetsa le ho thatafala ha ho molemo ho feta ho jara bolo ea tšepe ( The HRC of GCr15 steel ball ke 60- 66 ): kahoo , bophelo bo khuts'oane ha bo bapisoa.

Kopo:

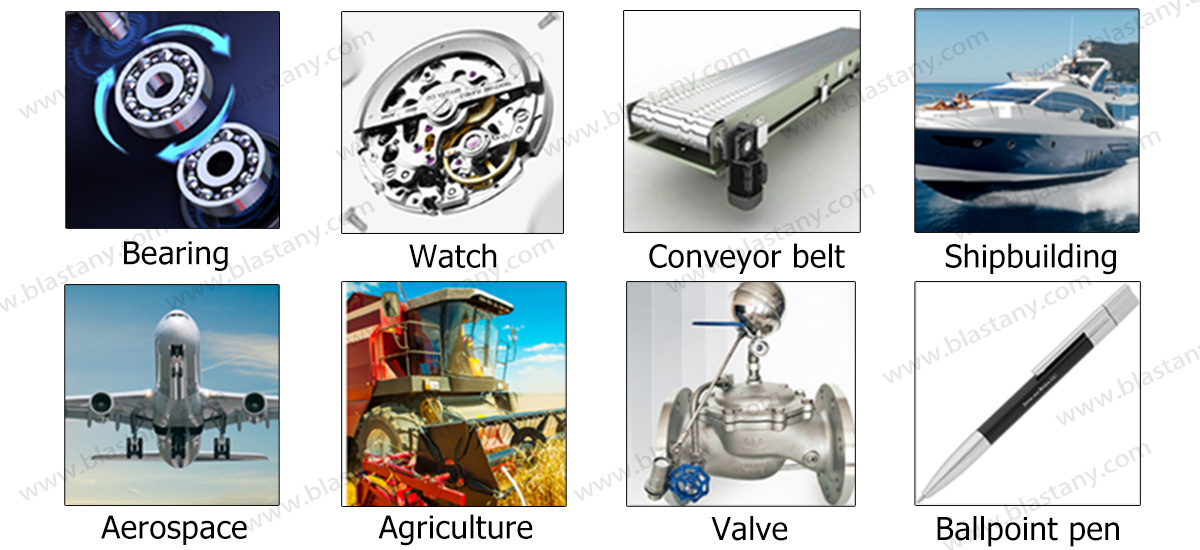

1010/1015 carbon steel ball ke bolo e tloaelehileng ea tšepe, e na le theko e tlase, ho nepahala ho phahameng le ts'ebeliso e pharaletseng. E sebelisoa ho libaesekele, li-bearings, mabili a ketane, mesebetsi ea matsoho, lishelefo, bolo e feto-fetohang, mekotla, lisebelisoa tse nyane, e ka sebelisoa hape bakeng sa ho hohla li-medium.Castors, Dressers' Bearings, Locks, Oilers And Grease Cups, Skates.drawers Slides And Window Rolling Bearings, Toys, Finishing And

| MOFUTA MOSEBETSI | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 | 0.10-0.35 | 0.30-0,60 | 0.04 | 0.05 |

| AISI 1015 (C15) | 0.12-0.18 | 0.10-0.35 | 0.30-0,60 | 0.04 | 0.05 |

Ball ea tšepe e phahameng ea Carbon

| Lintho tse bonahalang | AISI1085 |

| Boholo Range | 2mm-25.4mm |

| Kereiti | G100-G1000 |

| Ho thatafala | HRC 50-60 |

Tlhaloso ea Sehlahisoa

Likaroloana:

AISI1070/1080 Libolo tsa Carbon Steel, & Libolo tsa tšepe tse phahameng tsa carbon li na le molemo o makatsang ho latela index ea hardness eohle, e ka bang 60/62 HRC mme e fana ka ts'ebetso e phahameng ea ho roala le ho hanyetsa ha ho bapisoa le libolo tse tloaelehileng tsa tšepe tse thata.

(1)Mokotla-thata

(2) Ho hanyetsa ho fokolang tlhaselong e senyang

(3)Moroalo o phahameng le bophelo bo bolelele ho feta bolo ea tšepe e tlase ea carbon

Kopo:

Lisebelisoa tsa libaesekele, li-bearings tsa libolo tsa thepa ea ka tlung, litataiso tse thellang, mabanta a lipalangoang, mabili a boima, lisebelisoa tsa ho tšehetsa libolo. Li-bearings tse nepahetseng tse tlase, lisebelisoa tsa libaesekele le tsa likoloi, li-agitator, li-skate, metjhini e benyang le ea ho sila, li-bearings tse tlase tse nepahetseng.

| MOFUTA MOSEBETSI | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1070 (C70) | 0.65-0,70 | 0.10-0.30 | 0.60-0.90 | 0.04 | 0.05 |

| AISI 1085 (C85) | 0.80-0.94 | 0.10-0.30 | 0.70-1.00 | 0.04 | 0.05 |

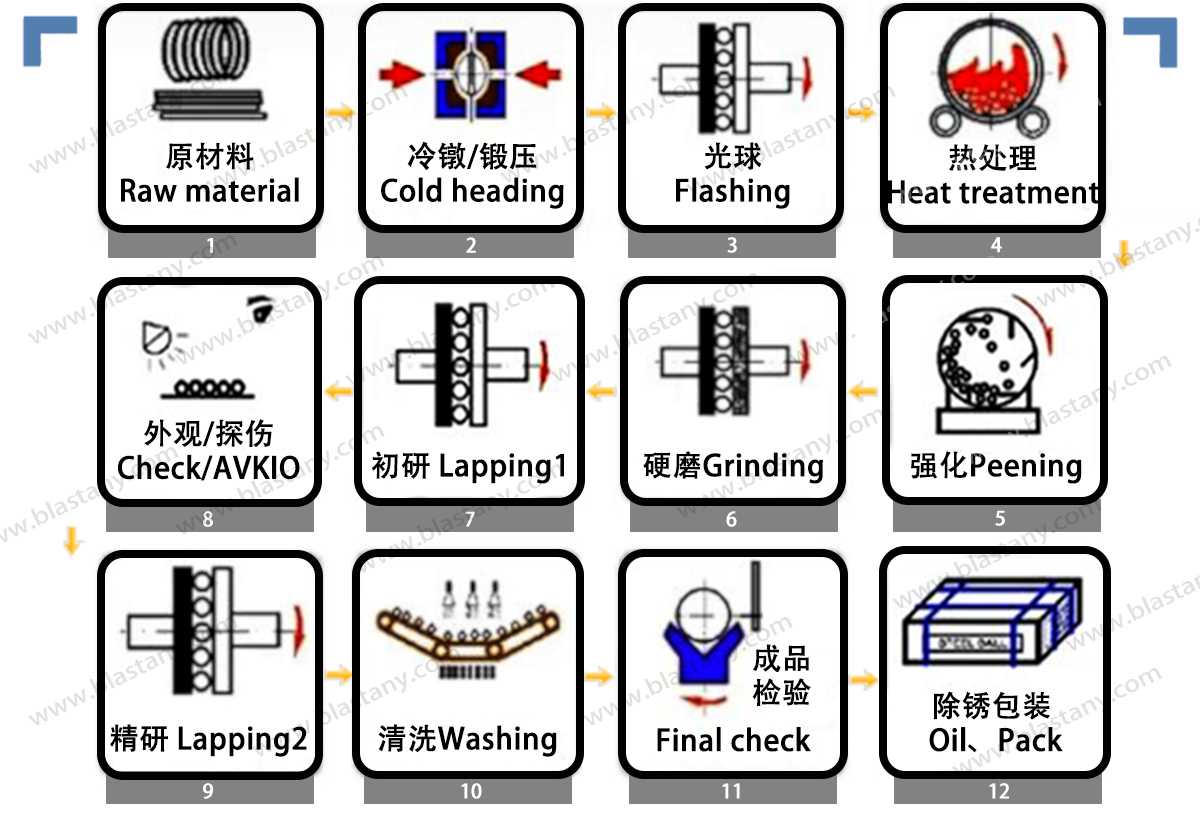

Mokhoa oa tlhahiso

Ts'ebetso ea Tlhahiso ea Lihlahisoa tsa Precision Ball

1.Molao Boitsebiso

Mehatong ea eona ea ho qala, bolo e qala ka mokhoa oa terata kapa oa molamu. Taolo ea boleng e feta tekong ea metallurgic ho netefatsa hore sebopeho sa thepa se ka har'a mekhahlelo e amohelehang.

2.Sehlooho

Ka mor'a hore thepa e tala e fete tlhahlobo, ebe e feptjoa ka hlooho ea lebelo le phahameng. Sena se etsa libolo tse thata haholo.

3. Ho benya

Mokhoa o benyang o hloekisa libolo tse nang le lihlooho e le hore li batla li le boreleli.

4.Kalafo ea Mocheso

Ts'ebetso ea mocheso o phahameng haholo moo libolo tse benyang li behoang ka ontong ea indasteri. Sena se thatafatsa bolo.

5.Ho sila

Bolo e siloa ho isa tekanyong e lekanang ea boholo ba bolo ea ho qetela.

6. Lapping

Ho qhoqhoa ha bolo ho e tlisa boemong boo e bo batlang. Ena ke ts'ebetso ea ho qetela ea ho theha 'me e fumana bolo ka har'a maemo a mamello.

7.Tlhahlobo ea ho Qetela

Joale bolo e lekanngoa hantle le ho hlahlojoa ke Quality Control ho netefatsa boleng bo phahameng ka ho fetisisa.

Lihlopha tsa lihlahisoa