10MM HO 130MM Ho Lahlela Ho Sila Mecha ea Mecha ea Ball bakeng sa Merafo ea Metal Mill le Limela tsa Samente

Tlhaloso ea Sehlahisoa

Mokhoa oa tlhahiso

Bolo ea ho lahla, eo hape e bitsoang bolo ea ho sila, e entsoe ka litšepe tse lahliloeng, tšepe e lahliloeng le lisebelisoa tse ling tse lahliloeng.Lisebelisoa tse boletsoeng ka holimo li qhibilihile haholo 'me li tsamaisa motlakase o tsoelang pele ka mor'a ho futhumatsoa.Nakong ea mokhahlelo oa ho qhibilihisa, palo e kholo ea likarolo tsa tšepe tse kang vanadium, tšepe le manganese li qala ho kenyelletsoa khase ea flue ho finyella chai e batloang le e reriloeng esale pele.Joale likarolo tsena li ka tšela tšepe e qhibilihisitsoeng ka mokhoa o fetisisang mokhoeng oa tlhahiso ea setsi sa ho etsa litšepe.

Kopo

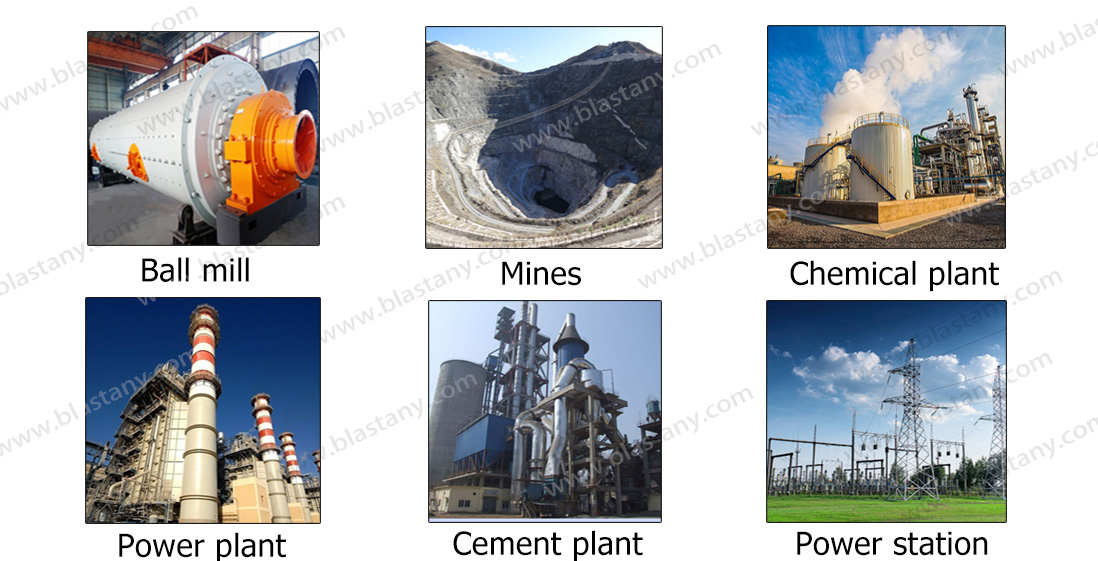

Casting Steel Ball e ka sebelisoa haholo lits'ebetsong tse fapaneng, ho kenyeletsoa

Feme ea lehlabathe la silika/Semela sa samente/Semela sa lik'hemik'hale/Setsi sa motlakase/Meepo/Liteishene tsa Motlakase

/Liindasteri tsa lik'hemik'hale/Leloala la ho sila/Ball mill/Leloala la mashala

Kenyelletso ea lihlahisoa tsa bolo ea tšepe

Libolo tsa tšepe tsa Chrome ke libolo tsa media tse silang tse nang le liperesente tse itseng tsa chromium, 'me li arotsoe ka libolo tsa tšepe tse phahameng tsa chromium, libolo tsa tšepe tsa chromium tse mahareng le libolo tsa tšepe tse tlase tsa chromium.Libolo tsa tšepe tse entsoeng ka chromium li arotsoe ka Libolo tsa Tšepe tse Phahameng tsa Chromium, Libolo tsa Tšepe tsa Chromium tse Bohareng le Li-Chromium Cast Steel Balls.Ka tšobotsi ea boima bo phahameng, ho roala tlaase, le ho robeha ha tlaase, libolo tsa tšepe tse entsoeng ka tšepe li sebelisoa haholo-holo indastering ea samente, indasteri ea merafo, indasteri ea metallurgic, indasteri ea tlhahiso ea matla le indasteri ea kaho.

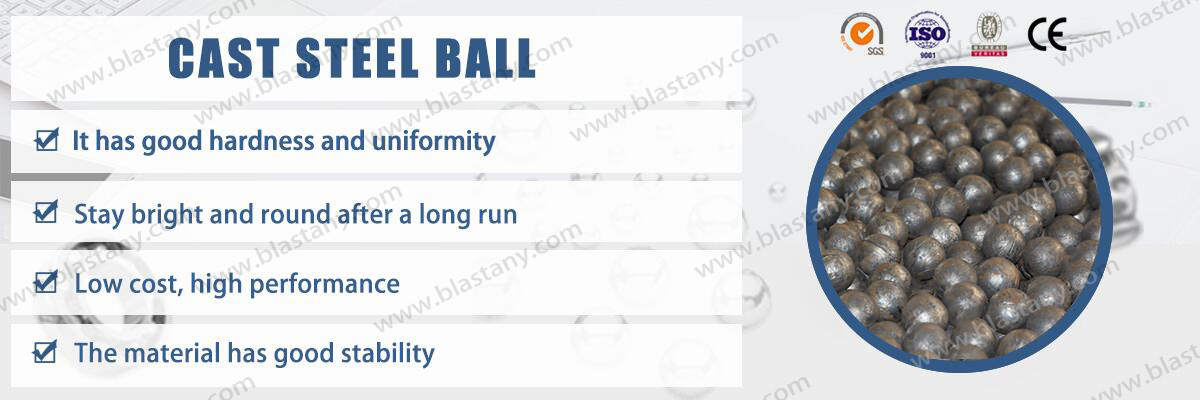

Cast Grinding Steel Ball Features

1, lisebelisoa tse tala kaofela li na le likhechana tsa tšepe, tse nang le koporo, molybdenum, nickel le likarolo tse ling tsa tšepe tsa bohlokoa, tse ka ntlafatsang sebopeho sa matrix sa bolo ea tšepe ka katleho.

2, Lihlahisoa tsa rona li hlahisoa ke sebōpi sa motlakase sa maqhubu a mahareng se ka netefatsang botsitso ba thepa.Libolo ha li bonolo ho ebola le ho holofala ha li sebelisoa.Le eona e ka lula e khanya ebile e pota-potile ka mor'a nako e telele e sebetsa.

3, Mohala o tsoetseng pele ka ho fetisisa oa ho tima oli o ikatisang o amoheloa bakeng sa kalafo ea mocheso, e netefatsang ho thatafala le ho ts'oana ha lihlahisoa.

Mekhoa e meraro ea ho etsa libolo tsa tšepe

1. Mekhoa e meraro ea ho etsa libolo tsa tšepe

Ho na le mefuta e meraro ea mekhoa ea ho etsa libolo tsa tšepe: ho lahla, ho qhekella le ho phutha.

(1) Ho lahla: Boleng ba libolo tsa tšepe tse entsoeng ka tšepe bo ipapisitse le litaba tsa chromium.Lilemong tsa morao tjena, theko e ntseng e phahama ea chromium, tšireletso ea tikoloho le lintlha tse ling li entse hore ho be le keketseho ea theko ea libolo tsa tšepe tse entsoeng ka tšepe.

(2) Ho qhekella: Ho sebelisa tšepe e phahameng ea manganese joalo ka thepa e tala, lihamore tsa ho etsa moea le liforomo tsa bolo li sebelisoa ho etsa libolo tsa tšepe.Libolo tsa tšepe tse entsoeng ka tšepe li na le motsoako o utloahalang oa k'habone e phahameng, manganese, chromium le likarolo tse ling tsa alloy, 'me li na le hardhardability e matla ea phekolo ea mocheso oa tlhahiso, phapang e nyenyane ea ho thatafala pakeng tsa ka hare le ka ntle, le phapang ea bohlokoa ba tšusumetso, dibolo tse betliloeng tse matla hofeta dibolo tse lahliloeng.

(3) Ho roala: Ho sebelisoa litšepe tse phahameng tsa manganese joalo ka lisebelisoa tse tala, libolo tsa tšepe li etsoa ke leloala la skew rolling le nang le li-spiral rollers.

| Ntho | Sebopeho sa Lik'hemik'hale(%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

|

Chrome e phahameng lahla libolo tsa gri nding | ZQCr12 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 11-13 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 |

| ZQCr15 | 2.0-3.0 | 0.3-1.2 | 0.2-1.0 | 14-17 | ≤0.10 | ≤0.10 | 0-1.0 | 0-1.0 | 0-1.5 | |

| ZQCr20 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤0.10 | ≤0.08 | 0-2.0 | 0-1.0 | 0-1.5 | |

| ZQCr26 | 2.0-2.8 | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤0.10 | ≤0.08 | 0-2.5 | 0-2.0 | 0-1.5 | |

| Middle chrome cast bal grinding ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 | 0.2-1.0 | 6.0-10 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | 0-1.5 |

| Libolo tse silang tsa chrome tse tlase | ZQCr2 | 2.0-3.6 | 0.3-1.5 | 0.2-1.0 | 1.0-3.0 | ≤0.10 | ≤0.08 | 0-1.0 | 0-0.8 | |

Litekanyetso tse phahameng tsa ho lahlela chromium (Paramethara ea Bolo ea Chrome e Phahameng)

| Bophara ba lebitso | Boima ba bolo e le 'ngoe ka kakaretso(g) | Bongata/ MT | Ho thatafala ka holim'a sefahleho (HRC) | Teko ea phello ea mamello(Linako) |

| φ15 | 13.8 | 72549 |

> 60 | >10000 |

| φ17 | 20.1 | 49838 | >10000 | |

| φ20 | 32.7 | 30607 | >10000 | |

| φ25 | 64 | 15671 | >10000 | |

| φ30 | 110 | 9069 | >10000 | |

| φ40 | 261 | 3826 | >10000 | |

| φ 50 | 510 | 1959 | >10000 | |

| φ60 | 882 | 1134 | >10000 | |

| φ70 | 1401 | 714 | >10000 | |

| φ80 | 2091 | 478 | >58 | >10000 |

| φ90 | 2977 | 336 | >10000 | |

| φ100 | 4084 | 245 | > 8000 | |

| φ120 | 7057 | 142 | > 8000 | |

| φ130 | 8740 | 115 | > 8000 |

Lihlopha tsa lihlahisoa