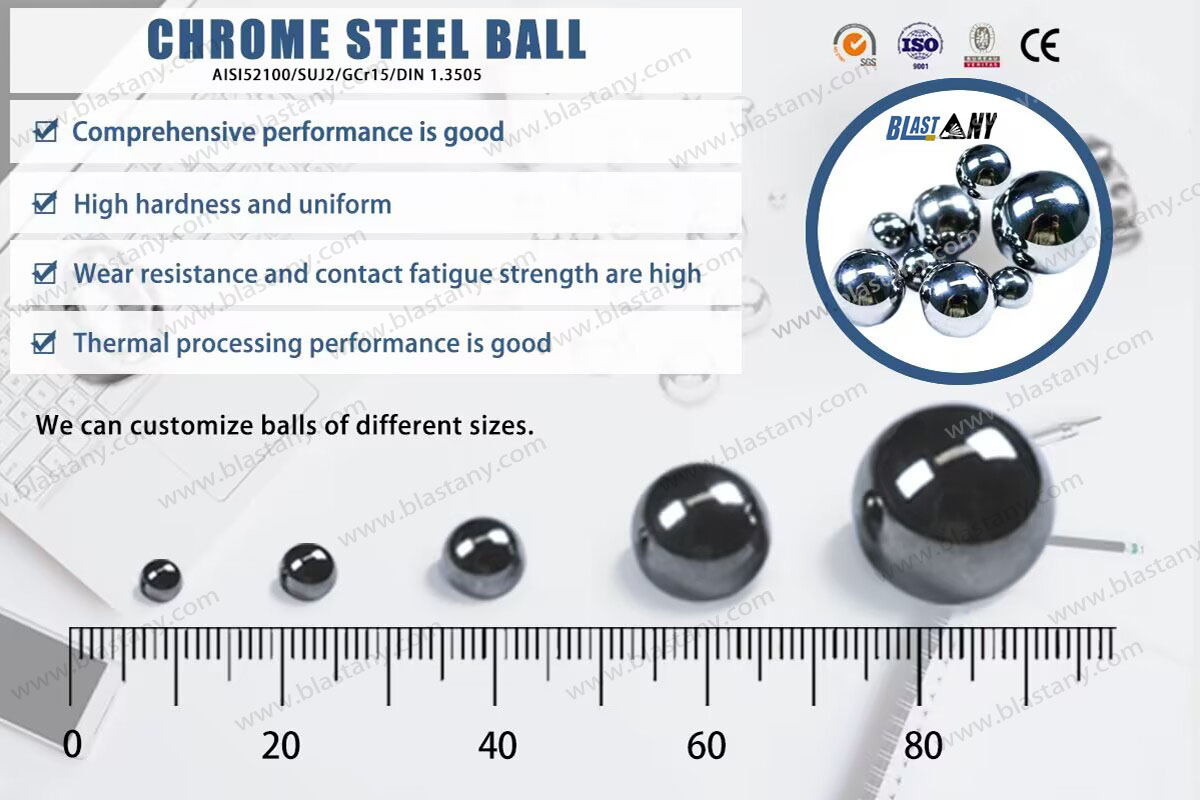

Boleng bo Phahameng AISI52100 GCr15 4mm G10-G1000 Chrome Steel Ball bakeng sa Lithuthuthu / Likarolo tsa Libaesekele/ Bearing Ball

Tlhaloso ea Sehlahisoa

Ka lebaka la litšoaneleho tsa eona tse khethehileng tse kang ho thatafala ho hoholo, khanyetso e phahameng ea ho roala, ho qeta hantle holimo le ho mamella maemo a tlaase, tšepe ea AISI 52100 chromium e tlaase e sebelisoa bakeng sa ho etsa li-bearings le li-valve.

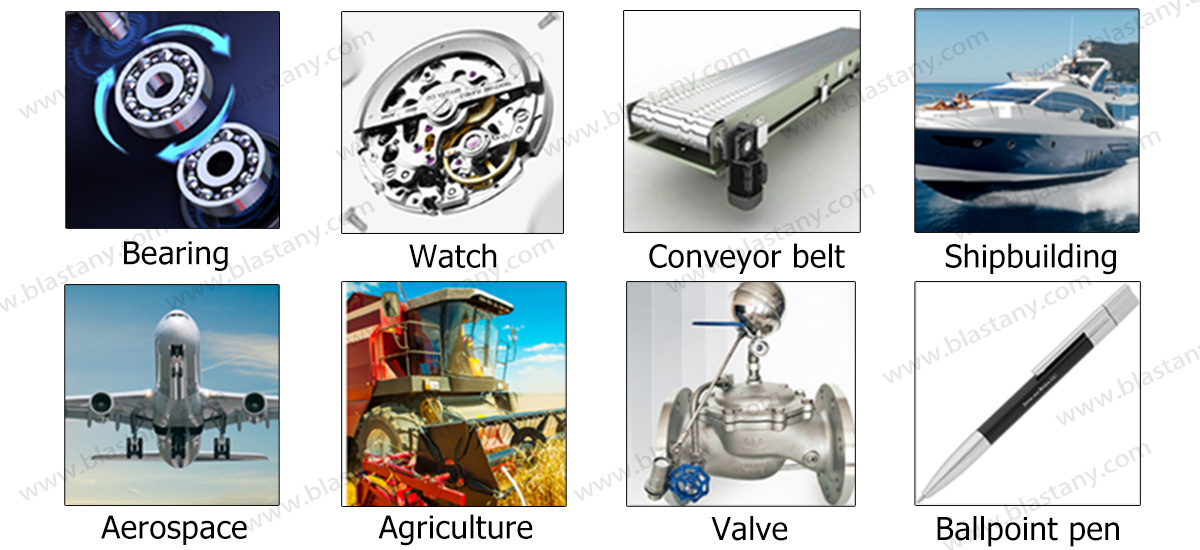

Libaka tsa kopo

Libolo tse roalang, li-valve, likhokahano tse potlakang, li-bearings tsa libolo tse nepahetseng, likarolo tsa koloi (mariki, seteraeke, phetiso), libaesekele, makotikoti a aerosol, litataiso tsa lirala, lisebelisoa tsa mochini, linotlolo, mabanta a tsamaisang thepa, lieta tsa slide, lipene, lipompo, mabili a bilikang, lisebelisoa tsa ho metha, li-screws tsa ntlo.

lenane la paramethara

| Bolo ea Tšepe ea Chrome | |

| Lintho tse bonahalang | AISI52100/SUJ2/GCr15/DIN 1.3505 |

| Boholo Range | 0.8mm-50.8mm |

| Kereiti | G10-G1000 |

| Ho thatafala | HRC: 60-66 |

| Likaroloana | (1) Ts'ebetso e felletseng e ntle. (2) boima bo phahameng le junifomo. (3) Ho hanyetsa ho apara le ho kopana le matla a mokhathala a phahame. (4) Ts'ebetso ea ts'ebetso ea mocheso e ntle. |

| Kopo | Libolo tse nang le Chrome tse sebelisoang haholo ho etsa libolo tsa tšepe, lirola le lihlahla holim'a litšepe tse kang lienjine tse tukang ka hare, literene tsa motlakase, lisebelisoa tsa mochini, literekere, lisebelisoa tse bilikang, lisebelisoa tsa ho cheka, likoloi tsa terene le mechini ea merafo. |

| Sebopeho sa lik'hemik'hale | ||||||

| 52100 | C | Si | Mn | P | S | Cr |

| 0.95-1.05 | 0.15-0,35 | 0.25-0.45 | 0-0.025 | 0-0.020 | 1.40-1,65 | |

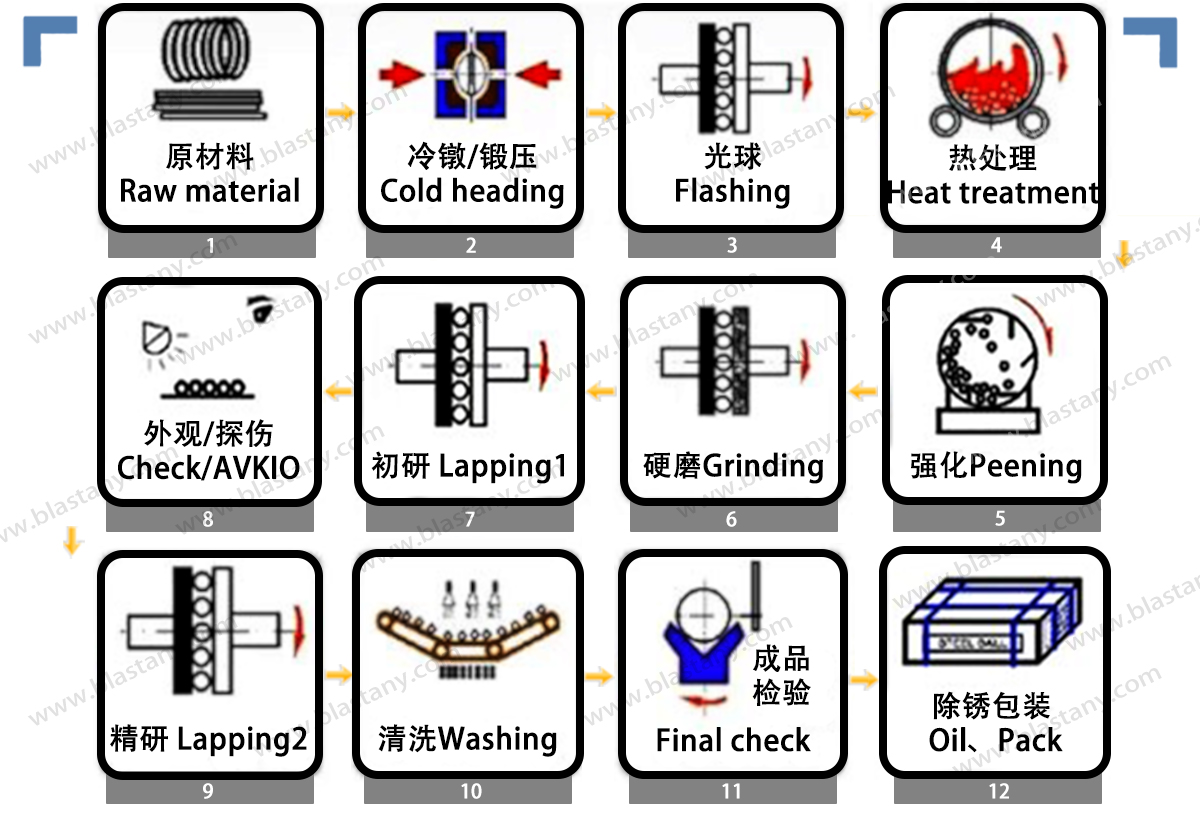

Mokhoa oa tlhahiso

Tlhahlobo ea Raw Material

Lintho tse tala li tla ka mokhoa oa terata. Taba ea pele, thepa e tala e hlahlojoa ke bahlahlobi ba boleng ho bona hore na boleng bo holimo le hore na ho na le lisebelisoa tse nang le bokooa. Taba ea bobeli, netefatsa bophara le ho lekola litifikeiti tsa thepa e tala.

Sehlooho se batang

Mochini oa sehlooho o batang o khaola bolelele bo itseng ba lisebelisoa tsa terata ho li-cylindrical slugs. Ka mor'a moo, lihalofo tse peli tsa hemispherical tsa sehlooho lia shoa li theha slug hore e be sebopeho se batlang se chitja. Ts'ebetso ena ea ho qhekella e etsoa ka mocheso oa kamore 'me ho sebelisoa lisebelisoa tse nyane tse eketsang ho etsa bonnete ba hore lesoba la lefu le tletse ka botlalo. Sehlooho se batang se etsoa ka lebelo le holimo haholo, ka lebelo le tloaelehileng la bolo e le 'ngoe e kholo motsotsoana. Libolo tse nyane li hasoa ka lebelo la libolo tse peli ho isa ho tse 'ne motsotsoana.

Ho benya

Nakong ea ts'ebetso ena, lisebelisoa tse feteletseng tse entsoeng ho pota-pota bolo li tla tlosoa. Libolo li fetisoa ka makhetlo a 'maloa pakeng tsa lipoleiti tse peli tsa tšepe tse entsoeng ka grooved li tlosa lintho tse nyenyane tse feteletseng ha li ntse li bilika.

Kalafo ea Mocheso

Joale likarolo li lokela ho phekoloa ka mocheso ho sebelisoa mekhoa ea ho tima le ho futhumatsa.Sebōpi sa rotary se sebelisoa ho etsa bonnete ba hore likarolo tsohle li na le maemo a tšoanang. Ka mor'a phekolo ea pele ea mocheso, likarolo li qoelisoa ka letamong la oli. Pholiso ena e potlakileng (ho tima oli) e hlahisa martensite, mohato oa tšepe o khetholloang ka ho thatafala ho phahameng le thepa e phahameng ea ho apara. Opereishene e latelang ea ho futhumatsa e fokotsa khatello ea maikutlo ho fihlela moeli oa ho ba thata oa li-bearings o fihletsoe.

Ho sila

Ho sila ho etsoa pele le ka mor'a phekolo ea mocheso. Qetella Ho Sila (hape e tsejoa e le Ho Hōla ka Thata) ho atametsa bolo haufi le litlhoko tsa eona tsa ho qetela.Mophato oa bolo ea tšepe e nepahetsengke tekanyo ea ho nepahala ha eona ka kakaretso; ha palo e le tlase, bolo ke eona e nepahetseng haholoanyane. Bophahamo ba bolo bo akaretsa mamello ea bophara, ho pota-pota (chitja) le bokaholimo ba bokaholimo bo boetseng bo bitsoang "surface finish". Ho etsa li-precision ball ke ts'ebetso ea batch. Boholo ba lotho bo khethoa ke boholo ba mochini o sebelisetsoang ho sila le ho phutha.

Lapping

Lapping e tšoana le ho sila empa e na le sekhahla se tlase haholo sa ho tlosa thepa. Lapping e etsoa ho sebelisoa lipoleiti tse peli tsa phenolic le seretse se setle haholo sa abrasive joalo ka lerole la daemane. Ts'ebetso ena ea ho qetela ea tlhahiso e ntlafatsa haholo bokaholimo ba bokaholimo. Lapping e etsoa molemong oa limaraka tse holimo-limo kapa tse nepahetseng haholo.

Ho hloekisa

Mosebetsi oa ho hloekisa o tlosa metsi leha e le afe a ho sebetsa le lisebelisoa tse setseng tsa abrasive ts'ebetsong ea tlhahiso. Bareki ba kopang litlhoko tse thata tsa ho hloekisa, joalo ka ba mafapheng a microelectronics, liindasteri tsa bongaka kapa tsa lijo, ba ka nka monyetla ka Hartford Technologies likhetho tse tsoetseng pele tsa ho hloekisa.

Tlhahlobo ea Pono

Kamora ts'ebetso ea mantlha ea tlhahiso, libolo tse ngata tse nepahetseng tsa tšepe li hlahlojoa khafetsa ts'ebetsong ea taolo ea boleng. Ho etsoa tlhahlobo ea pono ho hlahloba mefokolo e kang mafome kapa litšila.

Tlhahlobo ea Roller

Roller gauging ke mokhoa oa 100% oa ho hlopha o arolang libolo tsa tšepe tse nepahetseng ka tlase ho boholo le boholo bo fetelletseng. Ka kopo sheba sebaka sa rona se arohanengvideo ka mokhoa oa ho lekanya rolara.

Taolo ea Boleng

Bongata bo bong le bo bong ba libolo tse nepahetseng boa hlahlojoa ho netefatsa litlhoko tsa kereiti bakeng sa mamello ea bophara, ho pota-pota le bokaholimo ba bokaholimo. Nakong ea ts'ebetso ena, litšoaneleho tse ling tse amehang tse kang ho thatafala, le litlhoko leha e le life tsa pono li boetse li hlahlojoa.

Lihlopha tsa lihlahisoa