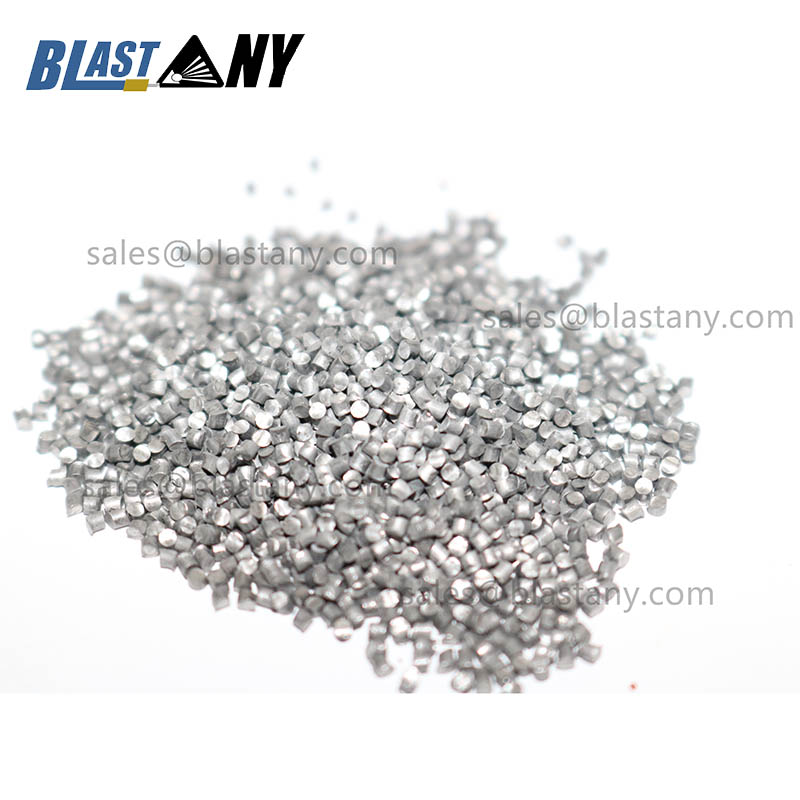

Theko e tlase bakeng sa Lithunya tsa Steel Shot S230 Sand Blasting Steel Shots bakeng sa ho Hloekisa Sebaka

Khoebo ea rona e khomarela molao-motheo oa "Boleng e ka 'na ea e-ba bophelo ba k'hamphani,' me rekoto ea eona e tla ba moea oa eona" ka theko e tlase bakeng sa Lithunya tsa tšepe tsa S230 Sand Blasting Steel bakeng sa ho Hloekisa Moaho, Litho tsa sehlopha sa rona li ikemiselitse ho fana ka thepa ka tekanyo e kholo ea litšenyehelo tsa ts'ebetso ho bareki ba rona, 'me sepheo sa rona kaofela ke ho khotsofatsa bareki ba rona ho tsoa hohle.

Khoebo ea rona e khomarela molao-motheo oa "Boleng e ka ba bophelo le feme, 'me rekoto e tla ba moea oa eona"China Steel Shot le Steel Grit, Bakeng sa mang kapa mang ea thahasellang ntho leha e le efe ea rona hang ka mor'a hore u shebe lethathamo la lihlahisoa tsa rona, ka sebele u lokela ho ikutloa u lokolohile ka ho feletseng ho ikopanya le rona bakeng sa lipotso. O khona ho re romella mangolo-tsoibila le ho ikopanya le rona bakeng sa lipuisano mme re tla u araba kapele kamoo re ka khonang. Haeba ho le bonolo, u ka fumana aterese ea rona sebakeng sa rona sa Marang-rang 'me u tle khoebong ea rona ho fumana lintlha tse ling tsa thepa ea rona ka bouena. Re lula re itokiselitse ho aha likamano tse atolositsoeng le tse tsitsitseng tsa tšebelisano le bareki leha e le bafe ba ka bang teng mafapheng a amanang.

Melemo ea Junda ho Waterjet Cutting

Garnet e tla ka mefuta e 'meli ea motheo, e sithabetseng le alluvial, eo hamorao e batlang e tšoana le lehlabathe le hlatsuoang holim'a linoka. Garnet ea rona ea ho romela kantle ho naha e hlahisoa ho tsoa ho crystalline almandite garnet ea rona le lehlabathe la noka la garnet. depositi. Ka lebaka la likarolo tsa eona tse bohale tsa ho pshatla, mofuta ona oa garnet o pshatlehileng o sebetsa joalo ka lisebelisoa tse bohale tsa ho itšeha e le hore e phahametse alluvial mme e bonts'itsoe hore e khaola hantle le kapele.

Meeli e Matla

Ka lebaka la Junda garnet sandis ea rona e pshatlehileng ho tloha lefikeng la almandine, e sebetsa joalo ka lisebelisoa tse bohale tsa ho itšeha 'me e ka khaola ka potlako le ka katleho ho feta alluvial garnet.

Ho poma ka potlako

E sithabetseng le ho khethoa ho tloha ho hard rock e le hore garnet ea boemo ba Junda waterjet e hlahise mapheo a thata le a bohale ho feta li-abrasives tse ling tsa waterjet. Litšobotsi tsena li nolofalletsa garnet ea rona ho tšoana le sesebelisoa se thata le se bohale sa ho itšeha ho qeta ho itšeha ka potlako.

Boleng bo botle ba Edge

Ho latela tlhokahalo ea boleng bo holimo, ho na le limaraka tse fapaneng tse khethehileng le tse nepahetseng tsa waterjet tse fanang ka boleng bo holimo.

Lerole le fokolang

Junda garnet e na le bohloeki bo phahameng ba garnet le lerōle le tlaase haholo. Seo se etsa hore thupelo eohle ea ho itšeha e be bonolo haholoanyane.

Ho khetha Mesh kapa Kereiti e nepahetseng

Junda e fana ka limaraka tse fapaneng ho tsamaisana le li-tube le li-orifice life kapa life bakeng sa lits'ebetso life kapa life tse fanoeng. Ho bohlokoa haholo ho khetha letlooeng kapa kereiti e nepahetseng bakeng sa ts'ebetso. Mefuta e fapaneng ea mesh ea garnet e etselitsoe ho feta ka har'a li-nozzles tsa boholo bo fapaneng mme ho khetha sehlopha se fosahetseng ho ka emisa ts'ebetso ea jet ea metsi ka botlalo. Haeba sehlopha sa garnet se le seholo haholo kapa se le mahoashe, li-granules li ka jeme ka har'a tube 'me li baka ho thibela. Ha e le hantle, abrasive e na le tšekamelo ea ho "kopana" hammoho ka hare ho hlooho e sehiloeng, 'me hape, e na le monyetla oa ho koala. Kapa e ka thibela ho phalla ha garnet ka har'a tube ea phepelo 'me e se ke ea kena ka mokhoa o tsitsitseng khoebong ea phallo ea metsi pakeng tsa lehakoe le nozzle. Haeba o sa tsebe hantle hore na ke letlooeng kapa kereiti efe e nepahetseng, ikutloe u lokolohile ho ikopanya le rona 'me re ka thabela ho u fa litlhahiso tsa rona tsa litsebi.

| E mahoashe | 60 Mesh |

| Mahareng | 80 Mesh |

| Hantle | 120 Mesh |

| Limaraka tse ling tse ntle | 150 letlooeng, 180 letlooeng, 200 letlooeng, 220 letlooeng |

Kakaretso ea Sebopeho sa Lik'hemik'hale (Tsa Tloaelehileng)

| Al2O3 | 18.06% |

| Fe2O3 | 29.5% |

| Ke O2 | 37.77% |

| MgO | 4.75% |

| CaO | 9% |

| Ke O2 | 1.0% |

| P2O5 | 0.05% |

| Mong O | 0.5% |

| Zr O2 | Mesaletsa |

| KHLORIDE SEHLOHO | Ka tlase ho 25ppm |

| TS'ELISITSOE MATSOSO | Ka tlase ho 100 ppm |

| PH EA METLO E KAROLO | 6.93 |

| TŠEBELETSO EA GYPSUM | Ha ho |

| MOTSOALLE | Ka tlase ho 0.5% |

| KARBONATE SEBAKA | Mesaletsa |

| TAHLEHELO KHOTHA | Ha ho |

| TŠEPANG TŠEPE | Mesaletsa |

Litšobotsi Tse Ling

| Sistimi ea Crystal | Likhubu |

| Tloaelo | Trapezohedron |

| Ho robeha | Sub-Conchoidal |

| Ho tšoarella | Hantle haholo |

| Phallo ea mahala | 90% Bonyane |

| Ho ba bonolo ho Acid | Ha ho letho |

| Mongobo oa Mongobo | Non Hygroscopic, Inert. |

| Magnetism | Magnetic e nyane haholo |

| Boikhantšo | Ka tlase ho 25 Microsiemens ka Methareng |

| Ketsahalo ea Radio | Ha e fumanehe kaholimo ho bokamorao |

| Liphello tsa Pathological | Ha ho letho |

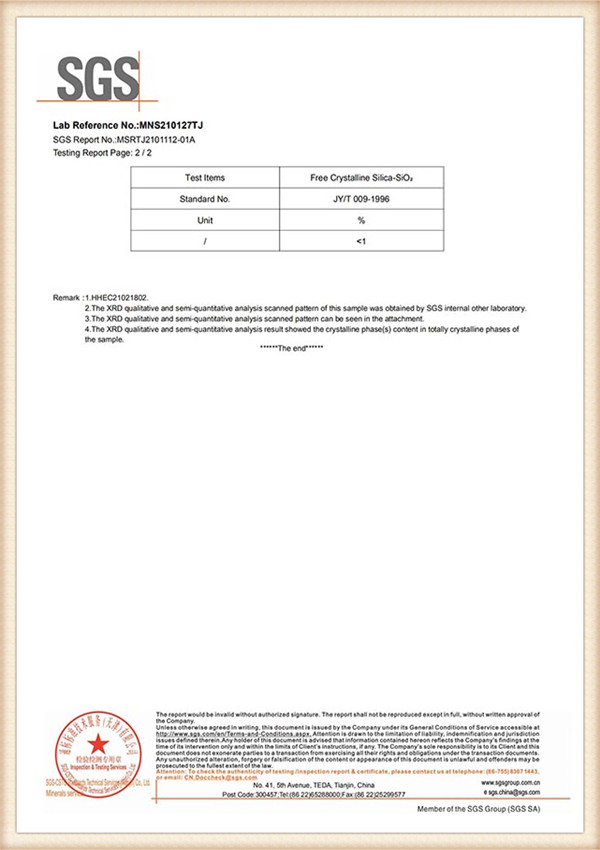

| Likahare tsa silika tsa mahala | Ha ho letho |

Sebopeho sa Mineralogical

| Garnet (Almandite) | 97-98% |

| Ilmenite | 1-2% |

| Quartz | <0.5% |

| Ba bang | 0.5% |

Litšobotsi Tsa 'Mele

| Boima bo itseng | 4.1 g/cm3 |

| Karolelano ea Bongata | 2.4 g/cm3 |

| Ho thatafala | 7 (Mohs Scale) |

| Mesh | Boholo ba MM | 16/30 MESH | 20/40 MESH | 20/60 MESH | 30/60 MESH | 40/60 MESH | 80 MESH |

| 14 | 1.40 | ||||||

| 16 | 1.18 | 0-5 | 0-1 | ||||

| 18 | 1.00 | 10-20 | |||||

| 20 | 0.85 | 20-35 | 0-5 | 0-5 | 0-1 | ||

| 30 | 0.60 | 20-35 | 30-60 | 10-25 | 0-10 | 0-5 | |

| 40 | 0.43 | 0-12 | 35-60 | 25-50 | 10-45 | 40-65 | 0-5 |

| 50 | 0.30 | 0-18 | 25-45 | 40-70 | 30-50 | 0-50 | |

| 60 | 0.25 | 0-5 | 0-15 | 5-20 | 10-20 | 15-50 | |

| 70 | 0.21 | 0-10 | 0-7 | 10-55 | |||

| 80 | 0.18 | 0-5 | 0-5 | 5-40 | |||

| 90 | 0.16 | 0-15 |

Kopo

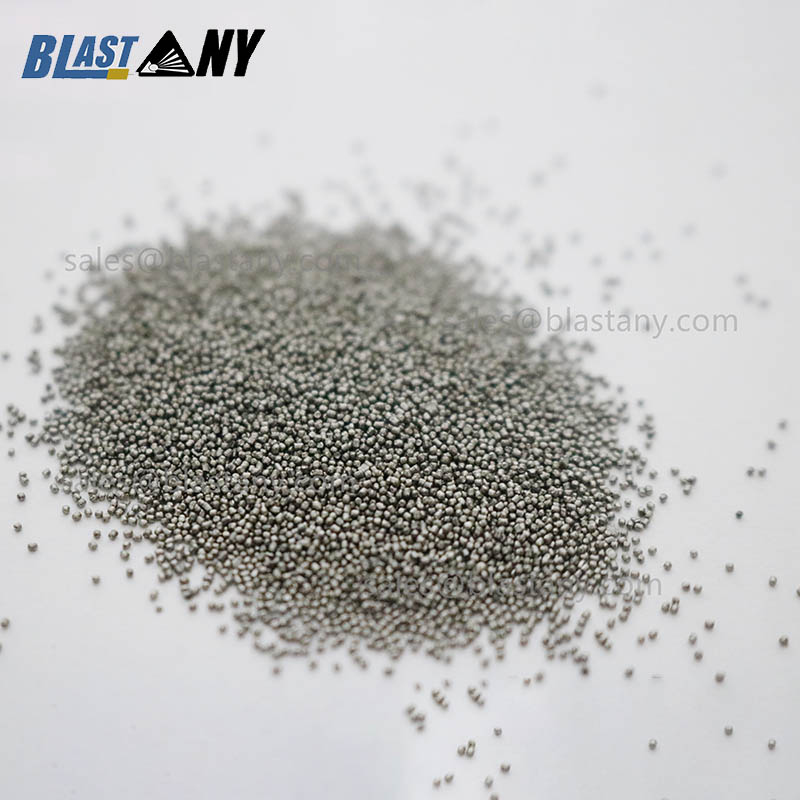

Ho qhomisa lehlabathe

Garnet sand abrasive e na le likarolo tsa ho thatafala ho hoholo, boima bo bongata bo phahameng, boima bo boima bo khethehileng, boima bo botle 'me ha ho na silica ea mahala. E sebelisoa haholo profilaneng ea aluminium, profil ea koporo, hlobo e nepahetseng, le likarolo tse ling tse ngata. 'Me e sebelisetsoa ho senya lehlabathe, ho tlosa mafome le ho phekola holim'a tšepe e sa hloekang, k'habone, mohaho oa tšepe, aluminium, titanium, likarolo tse entsoeng ka masenke, khalase, lejoe, lehong, rabara, borokho, kaho ea likepe, ho lokisa likepe, joalo-joalo.

Tlhophiso ea Metsi

Ka lebaka la eona boima bo boima bo itseng le thepa e tsitsitseng ea lik'hemik'hale. Lehlabathe la rona la garnet 20/40 # le ka sebelisoa e le mecha ea litaba e ka tlaase ea bethe ea filthara ka har'a metsi a hloekisang indasteri ea lik'hemik'hale, petroleum, pharmacy, ho hloekisa metsi a nooang kapa litšila. Ke e 'ngoe ea likhetho tse theko e boima ka ho fetisisa bakeng sa libethe tsa ho hloekisa metsi ho nkela lehlabathe la silika le lehlohlojane ka har'a tlhoekiso ea metsi, Haholo-holo e ka sebelisoa molemong oa litšepe tse se nang ferrous le seretse sa ho cheka seretse sa oli, hobane se seta bethe ea filthara kapele ka mor'a hore bethe ea filthara e khutlele morao.

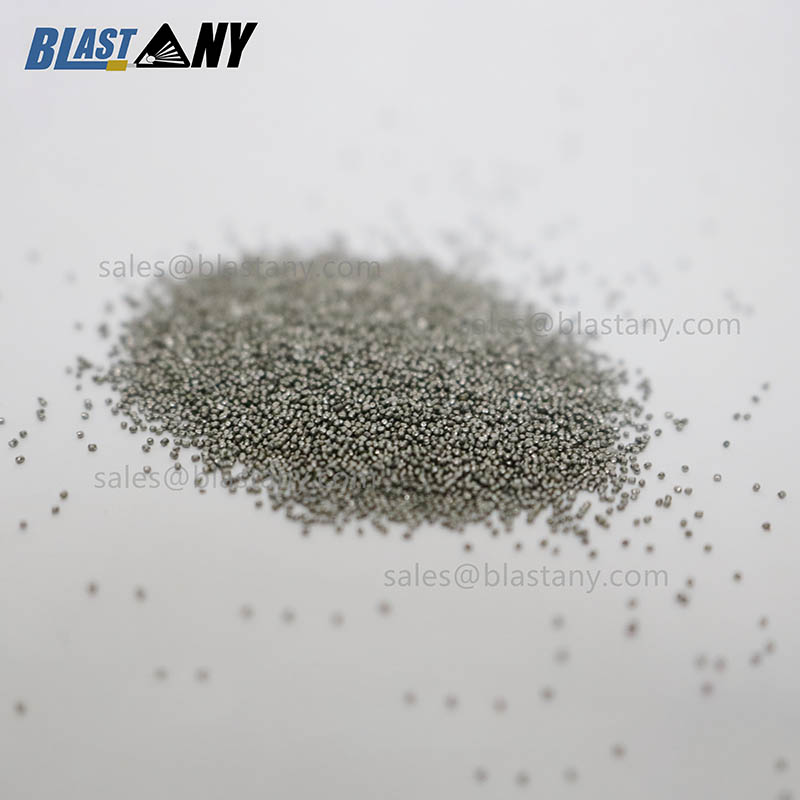

Ho Seha Jet ea Metsi

Lehlabathe la rona la garnet 80 # le na le likarolo tsa ho robeha ha sub conchoidal, boima bo phahameng, boima bo botle le likarolo tse bohale. Ho itšeha ka jete ea metsi ho sebelisa lehlabathe la garnet e le mokhoa oa ho itšeha, ho itšetlehile ka lijete tsa metsi tse nang le khatello e phahameng ea metsi ho nosetsa liphaephe tsa jete tsa oli le khase, tšepe le likarolo tse ling, tšepe e sa hloekang, koporo, tšepe, 'mabole, lejoe, rabara, khalase, lirafshoa. Hape bakeng sa lebelo la eona le phahameng le mokhoa o phollatsi oa ho itšeha ka jete ea metsi, e ke ke ea jama sesebelisoa sa ho itšeha se sebelisoang mochining oa ho itšeha oa jete oa metsi.

Moreki

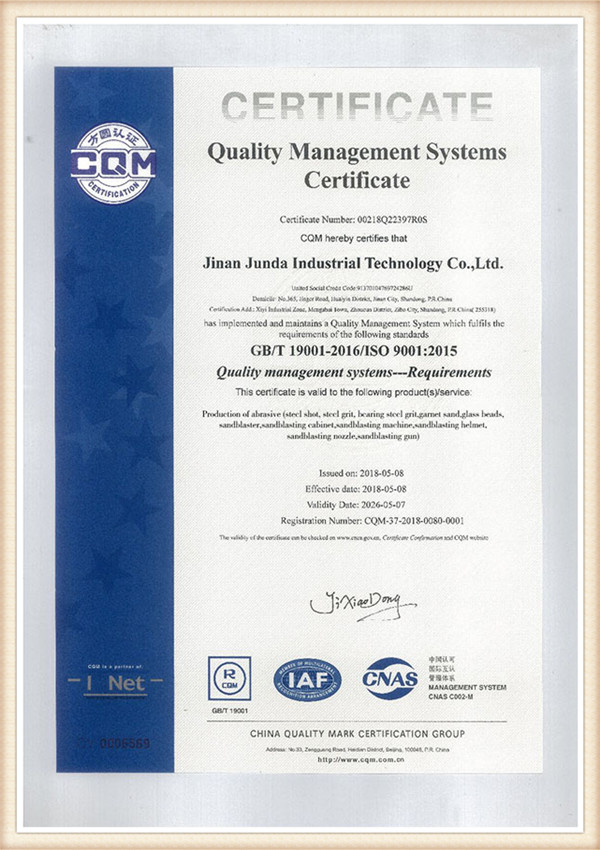

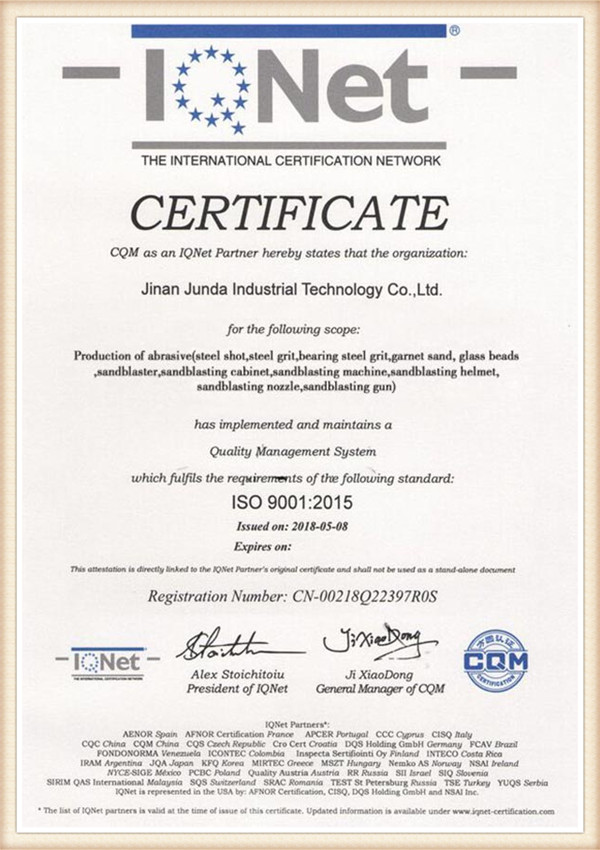

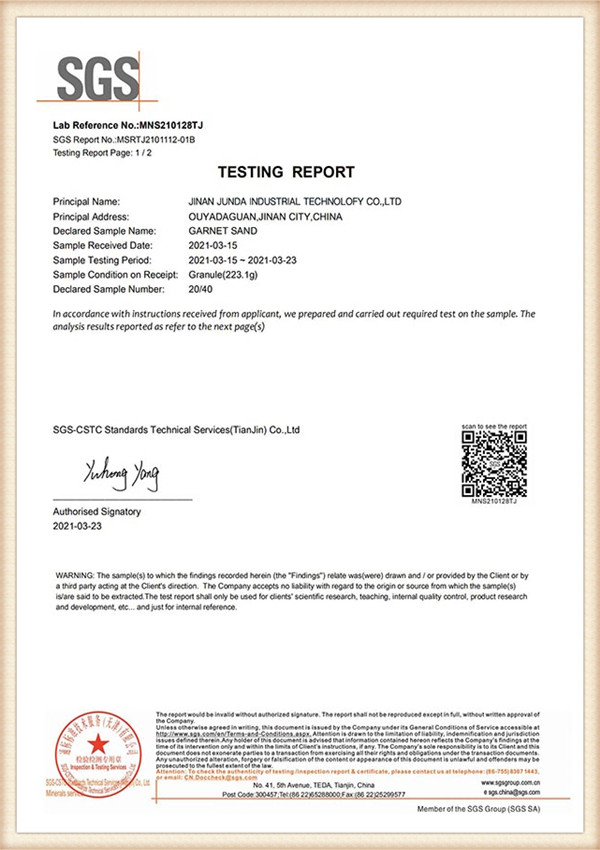

Setifikeiti

Khoebo ea rona e khomarela molao-motheo oa "Boleng e ka 'na ea e-ba bophelo ba k'hamphani,' me rekoto ea eona e tla ba moea oa eona" ka theko e tlase bakeng sa Lithunya tsa tšepe tsa S230 Sand Blasting Steel bakeng sa ho Hloekisa Moaho, Litho tsa sehlopha sa rona li ikemiselitse ho fana ka thepa ka tekanyo e kholo ea litšenyehelo tsa ts'ebetso ho bareki ba rona, 'me sepheo sa rona kaofela ke ho khotsofatsa bareki ba rona ho tsoa hohle.

Khoebo ea rona e khomarela molao-motheo oa "Boleng e ka 'na ea e-ba bophelo ba k'hamphani,' me rekoto ea eona e tla ba moea oa eona" ka theko e tlase bakeng sa Lithunya tsa tšepe tsa S230 Sand Blasting Steel bakeng sa ho Hloekisa Moaho, Litho tsa sehlopha sa rona li ikemiselitse ho fana ka thepa ka tekanyo e kholo ea litšenyehelo tsa ts'ebetso ho bareki ba rona, 'me sepheo sa rona kaofela ke ho khotsofatsa bareki ba rona ho tsoa hohle.

Theko e tlase bakeng saChina Steel Shot le Steel Grit, Bakeng sa mang kapa mang ea thahasellang ntho leha e le efe ea rona hang ka mor'a hore u shebe lethathamo la lihlahisoa tsa rona, ka sebele u lokela ho ikutloa u lokolohile ka ho feletseng ho ikopanya le rona bakeng sa lipotso. O khona ho re romella mangolo-tsoibila le ho ikopanya le rona bakeng sa lipuisano mme re tla u araba kapele kamoo re ka khonang. Haeba ho le bonolo, u ka fumana aterese ea rona sebakeng sa rona sa Marang-rang 'me u tle khoebong ea rona ho fumana lintlha tse ling tsa thepa ea rona ka bouena. Re lula re itokiselitse ho aha likamano tse atolositsoeng le tse tsitsitseng tsa tšebelisano le bareki leha e le bafe ba ka bang teng mafapheng a amanang.

Lihlopha tsa lihlahisoa