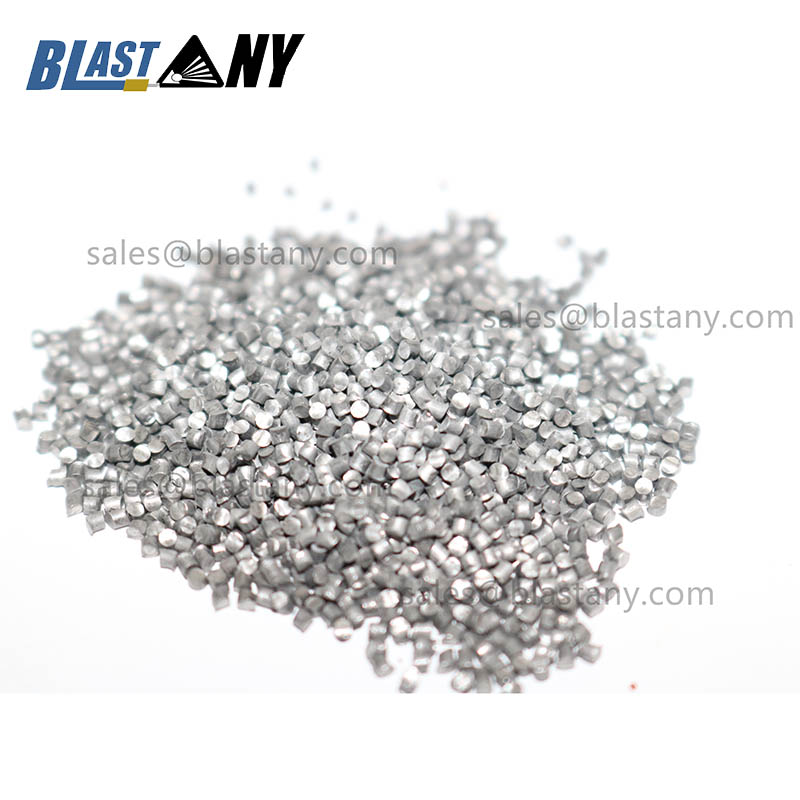

Matla a phahameng a khathatsoa ke mokhathala Cut Wire Shot

Mofuta oa terata ea tšepe

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Sebaka sa ts'ebeliso ea lipilisi tsa terata

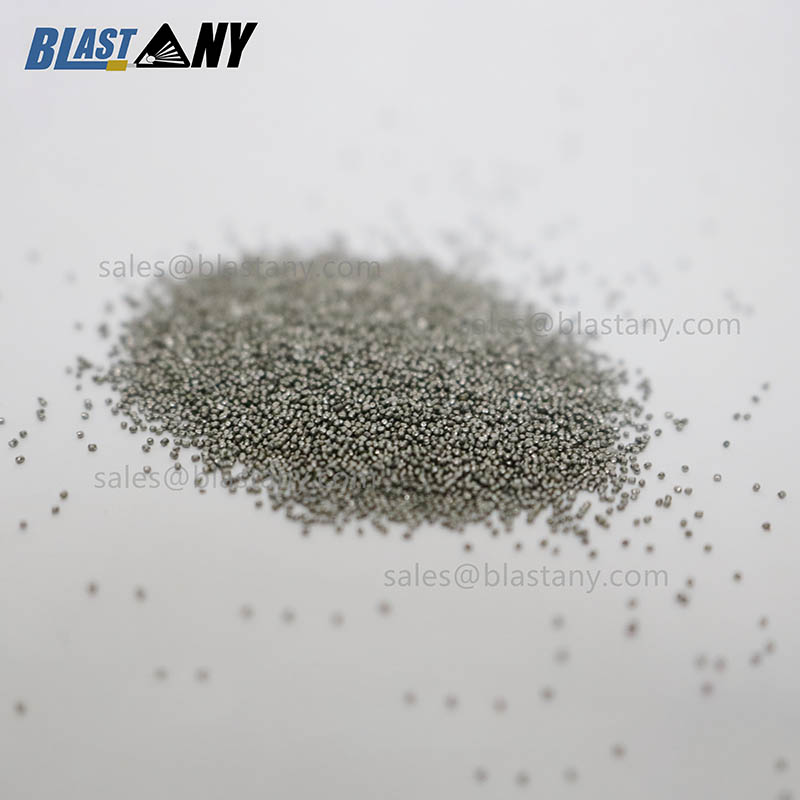

1. Steel terata e thunngoa ho itšeha ho matlafatsa: ho thunya ho matlafatsa ho matlafatsa, ho thunngoa ho matlafatsoa ha likarolo tse tšoaroang ke mocheso, ho thunya ho matlafatsoa ha lisebelisoa.

2. Ho phunya terata ea tšepe: ho phunyeha ha tšepe, ho phatloha ha lehlabathe la tšepe, ho qhomisoa ha lithunya tsa sekepe, ho phunyeletsa ha tšepe.

3. Ts'ebetso ea tšepe ea tšepe, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa lehlabathe, ho hloekisa lehlabathe, ho hloekisa tšepe, ho hloekisa tšepe, ho hloekisa tšepe, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa, ho hloekisa lehlabathe, ho hloekisa lehlabathe, ho hloekisa tšepe, ho hloekisa tšepe.

4. Steel wire cutting shot derusting: shot blasting derusting, shot peening derusting, casting derusting, forgings derusting steel plate derusting, forgings derusting, steel derusting, H-beam derusting steel structure derusting.

5. tšepe terata seha thunngoa lehlabathe: lehlabathe kalafo.

6. Steel terata thunngoa seha pretreatment: barbotage pretreatment, barbotage pretreatment, bokaholimo pretreatment, sekepe pretreatment, karolo tšepe pretreatment, tšepe pretreatment, tšepe pretreatment, tšepe sebopeho pretreatment.

7. Ho phatloha ha terata ea tšepe: ho phatloha ha tšepe ea tšepe, ho phatloha ha tšepe, ho qhomisoa ha tšepe.

Lisebelisoa tse sebetsang bakeng sa ho itšeha ka terata ea tšepe

Tšepe terata ho itšeha seha sebelisoa bakeng sa tšepe pretreatment tlhahiso line, tšepe pretreatment tlhahiso line, tšepe sebopeho pretreatment tlhahiso line, ho thunngoa ho qhomisa mochine, ho thunngoa ho qhomisa thepa, ho thunngoa ho qhomisa thepa, lehlabathe qhomisa mochine, lehlabathe blasting thepa abrasive.

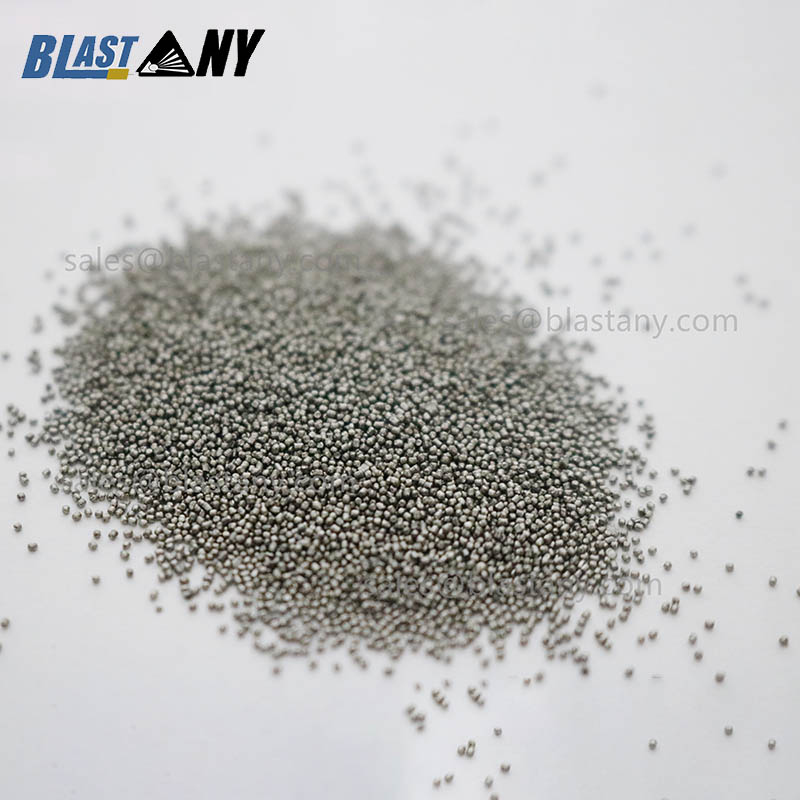

Tekheniki Parameters

| Lihlahisoa | Seha Wire Shot | |

| C | 0.45–0.75% | |

| Mn | 0.40–1.20% | |

| Sebopeho sa Lik'hemik'hale | Si | 0.10–0.30% |

| S | 0.04% | |

| P | 0.04% | |

| Microhardness | 1.0mm 51~53 HRC(525~561HV) | |

| Tensile Intensity | 1.0mm 1750 ~ 2150 Mpa | |

| Botenya | 7.8g/cm3 | |

Lihlopha tsa lihlahisoa